Table of Contents

- 1 Drill Definition/ Drill Meaning

- 2 Picture of Drill

- 3 List of Different Types of Drills: Names of Drills

- 3.1 #1. Hand drill/eggbeater drill:

- 3.2 #2. Brace drill:

- 3.3 #3. Bow drill:

- 3.4 #4. Crank drill:

- 3.5 #5. Gimlet:

- 3.6 #6. Breast drill:

- 3.7 #7. Push drill:

- 3.8 #8. Pin chuck:

- 3.9 #9. Corded drill:

- 3.10 #10. Battery drills/cordless drills:

- 3.11 #11. Pneumatic/air drills:

- 3.12 #12. SDS/rotary hammer drill:

- 3.13 #13. Hammer drill:

- 3.14 #14. Pillar drill:

- 3.15 #15. Table drill:

- 3.16 #16. Drill press:

- 3.17 #17. Impact drill/percussion drill:

- 3.18 #18. Impact driver:

- 3.19 #19. Impact wrench:

- 3.20 #20. Magnetic drills:

- 3.21 #21. Screwdriver drill:

- 3.22 #22. Bench drill:

- 3.23 #23. Antique drill:

- 3.24 #24. Radial arm drill:

- 3.25 #25. Ratchet drill:

- 3.26 #26. Vertical drill:

- 3.27 #27. Combi drill:

- 3.28 #28. Mechanic drill:

- 3.29 #29. Hex drill:

- 3.30 #30. Deck drill:

- 3.31 #31. Autofeed drill:

- 3.32 #32. Mill drill:

- 4 12v vs 18v drill

- 5 Final Words:

Last Updated on January 10, 2025 by John Patterson

Throughout the entire article, we covered almost all the different types of drills and their uses in 2025. Nowadays, almost everybody knows the tool ‘drill machine’ but how many of them know the vast fields of these tools?

Well, we know that we can make a hole using a drilling machine, but there are different kinds of drills we need to know about knowing which one we can apply where.

Which drill do you need? Let’s watch the video

You may know a drilling machine as an essential tool for your garage. Besides, there are many more uses of them as well as drill types. Some may be small in size, and others may be bigger. So here I am going to discuss different types of drills and their uses. Stay here with me to know their features and uses.

Before going to discuss what does drill mean and see the drill pictures, let’s see the list of topics we covered:

- Types of hand drills

- Types of power drills

- Types of cordless drills

- Types of electric drills

- Types of Hammer drills

- Types of school drills

- Types of emergency drills

Drill Definition/ Drill Meaning

A drill is a tool that you can use for boring holes or fastening materials together. It has a cutting tool attachment or instead of it a driving tool attachment. At one end of the drill, there is a chuck; it rotates when you press it against the target material.

The tip of this tool does cutting into the material. In woodworking, metalworking, or construction, people frequently use this tool. Some particular drill types used in medicine and space missions.

These have power and capacity characteristics. Over the last century, multiple sizes and types of drilling machines have been invented.

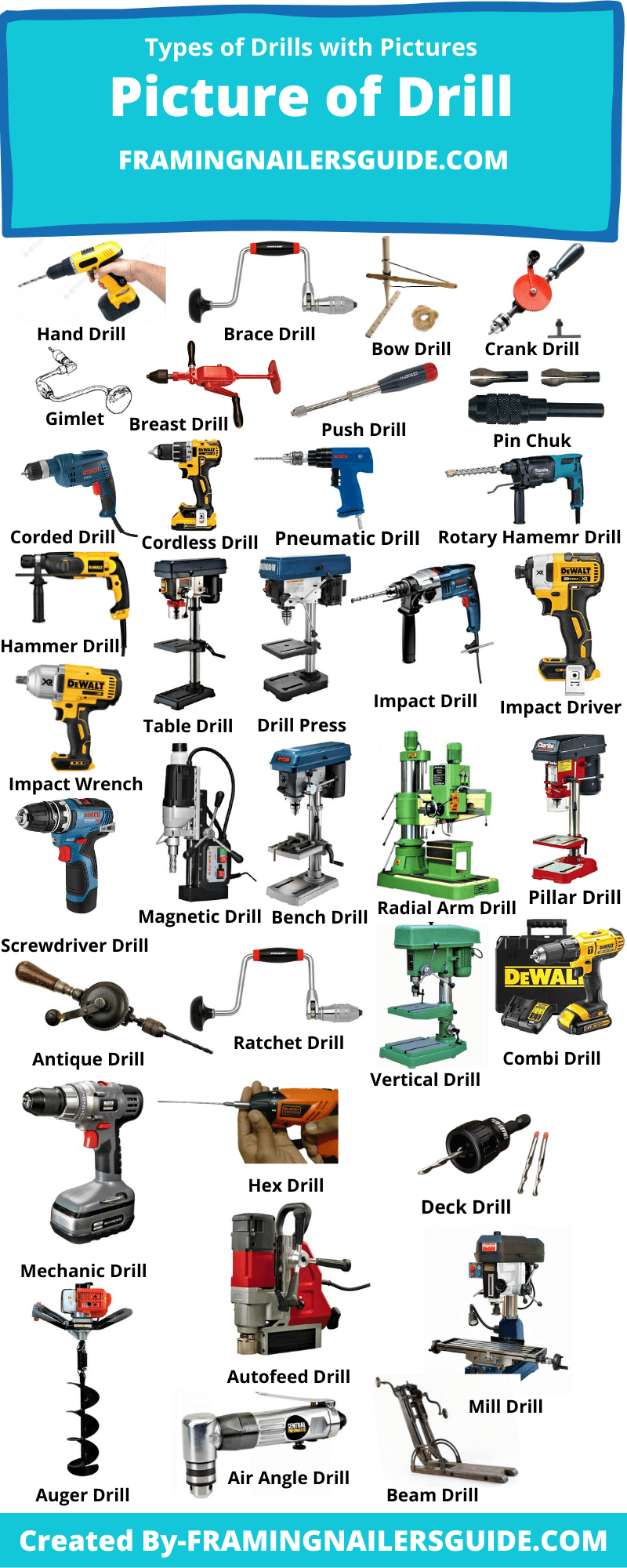

Picture of Drill

List of Different Types of Drills: Names of Drills

To work with drills, you should know about different types of drills and their uses. Here is a list of drills and their uses:

#1. Hand drill/eggbeater drill:

Features:

First to know about hand drill is, it’s a manual tool, it is gear driven. This tool has a driving wheel. You can spin it by using the turning handle.

When the wheel spins, the drill moves with the chuck. And it causes the bit to rotate. Who doesn’t want to use a power drill can choose the hand drill. Many woodworkers use this tool.

Uses:

One can use this hand tool for drilling small holes. Sometimes it is difficult to make a small hole with other drills, but you can do it using a decent hand drill. A hand drill can quickly create a small hole in softwood and soft metals.

Our Recommended best-suited Hand Drill:

#2. Brace drill:

Features:

Another manual drill is the brace drill. It has a U-shaped spindle which is cranked to lend more torque. That has another spindle on the top for gripping and fixing it in the desired position.

When working with it, hold one spindle with one hand and use another hand to rotate the second spindle in the clockwise direction. Therefore, you can make a precise hole using this tool.

Uses:

The use of the tool is in countersinking in the wood. You can also pierce wood utilizing the device. Other tools may not work in this case, but a quality brace drill is useful.

#3. Bow drill:

Features:

Another name of the bow drill is a fire drill. There has a bearing block, a spindle, a hearth, and a bow. It is a way of starting a fire without matches. By applying friction, generates heat. The heat produces ember in the sawdust.

Tinder bundle forms by the amber, and it bursts into the flame. One end of the spindle reduces the friction to maximizes at the other end. The bearing block holds one end and the baseboard the other. The string helps to tight enough so that it does not slip.

Uses:

The frequent use of it is to make friction fire. With the same principle, you can do woodworking and dentistry.

#4. Crank drill:

Features:

A crank drill is a twist drill that can make deep holes into harder materials. It has a high helix angle that increases penetration efficiency. And it has a sharpened tip to improve the cutting ability of the drill machine.

Uses:

You can quickly drill into hard materials like steel and metal alloys. Curve surface drilling is also possible with this tool. If you centered it once, it wouldn’t slip, it has the accuracy.

#5. Gimlet:

Features:

A gimlet is the larger version of the auger. It is a long drill bit that has a pair of handles for rotating it. And it looks like a corkscrew. The principle of a gimlet is based on leverage.

If the handle is more extended, you can apply a more significant force. You can also use it as an auger and reamers. Some are so huge that anyone can’t operate the tool. So you need a lot of experience to run it.

Uses:

To drill a broad and deep hole in the wood where you can’t get a great result using a bow or pump drill, use a gimlet. You can also use this to bore water pipes.

#6. Breast drill:

Features:

Breast drills are about 15 inches long and have a concave plate. The plate gives the user support to lean when boring a hole. The other names of breast drills are – chest drills, belly drills, and knee drills.

The design is such that the worker can put body weight when doing something. The tool is useful if you are willing to do the job in a standing position.

Uses:

Breast drill is necessary for the construction industry, factories, and blacksmith shops. Also, these are going to need in the rail car fabricated shops. You need a top-quality breast drill for boring holes in iron and steel.

#7. Push drill:

Features:

A push drill is a hand-powered drilling machine. It is a lightweight tool, and along with this, it is much more powerful than many other drilling machines. A push drill is a small and slender hand drill. Besides that, there has a spiral ratchet that rotates the bit.

Uses:

In woodworking, the tool has a precise place. These can give excellent results because of their lightweight. An impact drill or hammer drill is bulky, in that place a quality push drill can deliver you the exact result.

#8. Pin chuck:

Features:

A pin chuck is small in size. It has bits between 0 to 2.5 mm which are more modest in size than any other. It is a tool that holds small diameter drill bits.

There are different sizes of collets inserted in a pin chuck; the diameter varies from one to another. A pin chuck has two parts: head and collet jaws. There may have 3 to 4 jaws in a pin chuck.

Uses:

Its primary function of it is to drill small holes when other drills can’t do this. It is possible because of the tiny diameter drill bit. Watch repair and jewelry work need this tool as these are small in size.

#9. Corded drill:

Features:

Corded drills need a continuous power supply from a socket. The pistol-grip design makes the tool more comfortable to use. If you do not have a power supply nearby then extending the wire you can continue your work.

Corded drills are too powerful and can come up with greater torque. When you need a high-performing drilling machine, then choose the one which has a greater Amp number. The amperage range of this tool is between 3 and10 and the torque is 40-inch pounds.

Uses:

As these drills have various sizes of bits, it is comfortable to use. You can use a corded drill for drilling into wood, fiberglass, metal, and plastic. You can fix anything and remove screws, sand, and polishing wood using the tool.

#10. Battery drills/cordless drills:

Features:

The shape of cordless drills is precisely like the corded drills. The difference is in the function of the batteries and weight. The weight of it is much lighter than the corded one. If the voltage is high, then the power will be greater.

The voltage capacity is between 6-and 24 volts; the voltage determines its weight. Besides that, you can carry this tool with you and can operate it without a power supply. But you need to recharge it before or in between the task.

Nickel-cadmium batteries are cheaper and more substantial, and lithium-ion batteries are lighter and more expensive.

Related Reading: List of Cordless drills.

Uses:

The tool works on wood, metal sheets, fiberglass, and plastic. All you need is a top-quality cordless drill. Not very suitable for massive drilling works such as working with hard concrete or masonry.

#11. Pneumatic/air drills:

Features:

Pneumatic or air drills work with the power of compressed air. The power of compressed air is forceful as well as steady. These are not as common as a hammer or battery-powered drills.

So, people do not use many of these drills. But the power of the tool is much high than any other drills. Here is our recommended pneumatic drill.

Uses:

Commercial and industrial sites hugely use tools like that provided enormous power. Dentists use a dental drill, and it is a pneumatic drill. Furthermore, a jackhammer is an air drill that you use.

#12. SDS/rotary hammer drill:

Feature:

The other names of the rotary hammer drill are a rotary hammer, roto hammer drill, masonry hammer. There is a mixture of two mechanisms in this tool- the primary dedicated hammer mechanism and a separate rotation mechanism.

Besides that, it can withstand percussive forces as SDS and carbide drills are designed in that way. Some design tools can only do masonry drilling and can’t hammer action. There was a steam-driven rotary drill powered by steam.

Uses:

The primary use of this great tool is in substantial materials like concrete or masonry. Some tools can deal with the works without hammer action so quickly.

#13. Hammer drill:

Features:

A hammer drill can sometimes provide you with hammer action and sometimes both rotary and hammer actions. With the rapid and short response, a hammer drill pounds through concrete, stone, and other thick metals.

You will find both cordless and corded hammer drills in the market. It has an extra stand that provides excellent support during hammering. Drill with more BPM (blows per minute) and IPM (impacts per minute) you should select.

To know more about the hammer drill and its differences from an impact driver, you can click this link.

Uses:

You can use a rotary hammer drill as a standard drill. If you are planning to drill into bricks, this one will be the best option. Above all, the ability to pound thick concrete makes the hammer drill more unique than any other drill.

#14. Pillar drill:

Features:

Pillar drilling machines are similar to tabletop drilling machines. But these have a larger size than the tabletop machines as well as higher capacity.

The capacity range is between 0.55 to 1.1 kW. The foundation of the pillar drill is from the ground which means it stands on the ground.

Above all, you can move the work table when necessary, and also can run the drill feed. The tool has tubular columns, and the tubular columns are much tall. It stands upon a base.

Uses:

The advantage of a good pillar drilling machine is these are low-cost machines that can provide you with excellent quality of work. Generally, you can use this tool for light drilling. When you need to do small jobs, it is the best one to choose from.

#15. Table drill:

Features:

A table drill machine does not have a particular field to use. The category of this tool is a general-purpose drilling machine.

It is a manually driven drill machine. The power of the device is low than many other drill machines as it has no power source for work.

There is a lever in these machines to feed. Using the tool, you can produce 10 mm in diameter. Furthermore, it may have a table along with it to provide comfort when working.

Uses:

Table drill can efficiently do any light job as it is manually driven. Heavy jobs are not their task to do. You can’t continue odd shape jobs using the tool.

#16. Drill press:

Features:

You will find a fixed or stationary drill machine in the market. It has motor and stationery bits attached to it. Using these parts, you can make multiple holes.

Most noteworthy, it is the most potent drilling machine. While the precise hole is making you need specific width and depth, choose the tool. You can also adjust the angle to make a hole.

Uses:

As these are so much power, you can use these to make a hole or drill the most robust materials. Besides that, you can use it to pierce softer materials.

#17. Impact drill/percussion drill:

Features:

An impact driver is a shorter drill machine than some of the other drilling machines. Most of the drills have a chuck, but an impact drill has a hexagonal socket instead of a chuck.

There may have an adapter to attach bits. If you do not need much power, this tool may seem like a cordless drill. Besides that, it has a unique mechanism that provides its force. It doesn’t have an adjustable clutch.

Uses:

When you need to drive fasteners and nails, go with a top-quality impact drill or percussion drill. You can also drill a hole using it. If you do not have a regular drill, then you can continue your work with an impact drill.

#18. Impact driver:

Features:

The rotation of an impact driver is similar to a regular drill machine. In the presence of resistance, it gives pounding movements and drives fasteners on the surface.

Most noteworthy, it is one shorter drill with much power. You can adjust different types and sizes of the bit to the chunk of it. Read this article to know the difference between an impact driver and a hammer drill.

Uses:

When traditional drills can’t perform massive works, an impact driver can do it with much ease. It is a type of drill that you can use for large projects. Building fences and decks can quickly be dealt with as an impact driver.

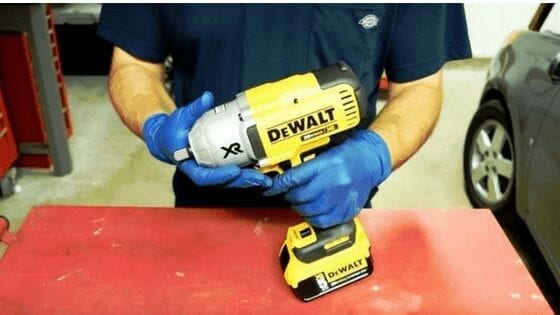

#19. Impact wrench:

Features:

Other names of an impact wrench are impactor, air wrench, rattle gun, etc. which is a power tools. It can deliver high torque and store energy. Impact wrench receives power mainly from compressed air; it also receives electric and hydraulic power.

Besides that, these have an available size of socket wrench drive. The mechanism is it can spin freely after delivering the impact.

Do you know the differences between an impact driver and an impact wrench? I think this article might help you.

Uses:

It has a massive use in many industries. Workers use it for automotive repair, heavy equipment maintenance, and major construction projects.

#20. Magnetic drills:

Features:

It is also called a magnetic drill press or portable drilling machine. A magnetic drilling machine has two types of bases; these are electromagnetic and permanent magnets.

Some devices have twist drill bits, and others have annular cutters. The two parts of this tool are a cutting tool attachment and an electromagnet. It uses metal core drilling technology to make a hole through any metal.

Uses:

Threading, reaming, and countersinking can quickly be done with a magnetic drill machine. It can make a hole through any metal.

For conventional drilling a machine it is tough to drill through thick steel whereas magnetic drills do this job with much ease.

#21. Screwdriver drill:

Features:

Screwdriver drills can produce more torque than regular drills. These have a lower rotation per minute. Therefore, it offers you control of this tool.

Besides that, some have torque limiters so you can select one specific torque for the work that you need. For this, set the drill’s cut-off. When using it, you don’t need to do the pre-drilling.

Uses:

You can use the tool for drilling into wood, and that does not require predrilling it. You can set maximum torque when using a decent screwdriver drill. If you are moving into an unfurnished home, this is a great tool to drill.

#22. Bench drill:

Features:

Benchtop drills are common among different types of drilling machines. You can work with it by mounting it on the bench or any table.

These are not much tall and have some restrictions on height. Even more, the motor of this tool is potent. It does not take much space so you can place it with other devices.

Uses:

It is a suitable one when you are dealing with wood projects. When doing essential drill works, it is the best drill machine to choose from.

#23. Antique drill:

Features:

Antique drills are mainly made of hardwood. It may be round-shaped or have something to grip. Augers are the type of antique drill. You can remove the chip from it to clear it. Furthermore, modern drills have fixed bots attached to them.

Uses:

The uses of antique drills are various. In furniture making, workers use this drill, again surgeons also use it. Sometimes it becomes an essential kitchen tool.

#24. Radial arm drill:

Features:

In radial arm drill, there has a large geared head, and you can move it along the arm. The main advantage of it is you can cover a large area of work without changing the position of the drilling machine.

Even more, it saves time as well as your strength because it is much more difficult to unclamp a tool than to reposition the head. There may have a vice with it and with every model a table is present. Most noteworthy, large sizes of radial arm drill machines have a motor attached.

Uses:

It is a versatile drilling machine in which you can deal with more substantial parts of any instrument. Even more, the most significant drill machines can make a hole of about 4 inches in diameter. It can make a hole through steel and cast iron.

#25. Ratchet drill:

Features:

It is a mechanical drilling machine that has two parts – a gear and a pawl. When you fit it, this tool will work in a circular motion and can rotate only in one direction. Most noteworthy, it can’t turn in another direction.

There are three ways and a 5-way ratchet mechanism. Which you will set for your job will be your decision. If you set 3 positions, then it is a three-way, and if you set 5 positions then it is a 5-way ratchet drill.

Uses:

When you have drilled a lot of holes and the space is not much large then you can go with a 5-way ratchet. A 3-way ratchet is available and less costly, much more adequate.

#26. Vertical drill:

Features:

The vertical drill is an upright drill press. Mostly, the vertical drilling machines are inverter driven, and you can run them at variable speeds. The speed range is between 0 to 2500 rpm, and the body of the vertical drill sits on a base.

Uses:

Fabrication shops prefer this tool. Again schools use the tool for saving space.

#27. Combi drill:

Features:

A Combi drill is a tool with various functions. It has the functions of a hammer drill which is the source of the impact and rotational forces.

Indeed, you need to slow down the speed when drilling into masonry. Where there needs high torque, the combi drill is the best in there.

Uses:

You can use a combi drill for various functions. If you don’t have an impact or hammer drill, you can do those jobs using a combi drill which you needed to do with those tools. Even more, it provides high speed which you will need for wood and metal.

#28. Mechanic drill:

Features:

A mechanic drill is a power drill. It can do both heavy and light jobs. Even more, it depends on the nature of the task. Most noteworthy, you have to maintain it properly to make it work for a long time.

Uses:

You can make a hole through heavy or softwood. Also, you make a drill through almost all the metals.

#29. Hex drill:

Features:

In the hex drill, there is a hex bit shank. There have several flats in the hex drill machine, the distance between the two flats is 10 mm. It may have a grasp of 3 jaw drill chuck.

Among all of the shanks, quarter-bit hex shanks are common for hex drills. Most noteworthy, it transmits high torque, but the strength has limitations.

Uses:

The tool can compete with the screwdriver machinery. Above all, the advantage of the tool is it can transmit high torque.

#30. Deck drill:

Features:

As it is used for drilling hard material, copper or coated steel is the material of the machine. The head type of it is countersunk, drive type is a square drive, pointed tip.

It has a tapered body, partially threaded. Even more, it is designed for all weather conditions.

Uses:

You can use it to drill both hard and softwood decking boards. It is a long-lasting material as it prevents corrosion.

#31. Autofeed drill:

Features:

You can use the drill machine by pressing only one button. It has a power feed cycle which helps to reduce the work done time.

You need not give much effort to working with this tool, but you have to have the skill for operating the tool. Indeed, there are various types of safety measures attached to this tool, so it is safe to use for any worker.

Uses:

The main advantage of using the tool is you can make several drills at a time with a single stroke. So is it useful when you need to drill many holes?

#32. Mill drill:

Features:

It is a light drilling machine and an alternative to the milling machine. There is a drill with it which has the ability in both horizontal and vertical directions.

Also, there has a locking collet. The advantage of the collet is it prevents from falling the cutting tool from the table. These are lightweight tools that save space.

It has versatility and is not a very expensive drilling machine. But it can’t deal with massive works.

Uses:

For any light task, you can undoubtedly choose the mill drill. Again if you have a space shortage, you can have this tool other than any drills which can do light works.

12v vs 18v drill

12v drill:

The 12v drill is less potent than an 18v drill. It is perfect for a pro carpenter as he can do all the work with it. The weight of the 12v drill is light. Using it is advantageous when you are in crawlspaces or working overhead. The size of the 12v drill is reasonable.

18v drill:

The 18v drill has more power than a 12v drill. If you are planning to do heavy-duty jobs or high-stress tasks, then using the 18v drill will be the right decision. As it is more powerful, the weight is also substantial. It is larger.

Final Words:

Finally, after going through the whole article, you now have a concept of which drill machine you can use for a particular job. So you don’t have to get confused over different types of drills, and which drill machine you should buy.

You can do your work smoothly with the information you have obtained from this article. So enjoy your work now!