Table of Contents

- 1 What are pneumatic tools powered by?

- 2 What Is Pneumatic Tools?

- 3 History of Pneumatic Tools

- 4 Types of Pneumatic Tools

- 5 How Pneumatic Tools Work?

- 6 Key Sections and Functions of Pneumatic Instruments

- 7 How to Select Compressor Types and Power Save?

- 8 Popular Uses of Pneumatic Tools in Various Industries

- 9 Workplace Safety Tips for Pneumatic Tools

- 10 Why Choose Pneumatic Tools? Benefits Over Electric Tools

- 11 Frequently Asked Questions

- 12 In Conclusion

Last Updated on November 19, 2024 by John Patterson

Well, are you prepared to dive right into the wonderful world of pneumatic tools? For DIYers, woodworkers and automotive professionals alike, pneumatic tools can take your projects to the next level… if you know how to use them.

In this article, we’re going to demystify these ancient tools, cover what makes them tick — and why you should use them as your go-to tool of choice if you’re a professional or hobbyist. After reading through this post, you should be able to confidently use pneumatic tools in your work!

What are pneumatic tools powered by?

Air tools (or pneumatic tools) are powered with compressed air. An air compressor provides this air, since this device converts power (using an electric motor, diesel or gasoline engine) into potential energy stored in pressurized air.

Compressed air is released in a regulated manner when you activate a pneumatic tool, and this is what makes things like drilling, sanding, or wrenching not only easier—but more efficient.

Pneumatics are simple and uncomplicated devices. There are no complex electronic circuits in it like battery-operated and electric tools, so they last longer, even in bad conditions. As such they are especially sought after in professional circles where long-term consistent performance is a priority.

What Is Pneumatic Tools?

Pneumatic tools (also known as Pneumatic hand tool) are drill that run on compressed air and serve various applications. Examples include nail guns, air hammers, sanders, spray guns and impact wrenches. They are indispensable in situations where high torque, precision, and speed are required—hence a workshop and industrial mainstay.

The main benefit of pneumatic (air-powered) tools is power-to-weight specifications, providing powerful tools free from the weight and size of electric motors. Users can operate them for long periods of time without fatigue. Another thing you need to consider is that pneumatic tools are generally lighter because they run on air, while electric tools will always be heavier since their motors tend to weigh more.

Whether you are a hands-on person who enjoys DIY or look for an efficient tool to handle various jobs, pneumatic tools can serve as the best choice providing both reliability and sufficient power. These tools can help you enjoy and accomplish more in your furniture building, vehicle maintenance, house painting, etc.

History of Pneumatic Tools

Pneumatic tools have been in use since the ancient times, even before human beings realised the potential that is lying behind compressed air. Nevertheless it wasn’t the industrial revolution that pneumatic developments began to progress. The invention of steam engines and the creation of compressors opened the door for more advanced pneumatic systems.

From the early 20th century, pneumatic tools became a mainstay in industries including mining and construction. Their workhorse qualities made them indispensable in getting these heavy-duty tasks done fast. Over the years, technology had funded more mature pneumatic tools with higher versatility and a greater common audience.

Pneumatic tools are common in modern automotive repair shops and the garages of home mechanics alike. The evolution continues with manufacturers looking for an update to meet what we are used to today.

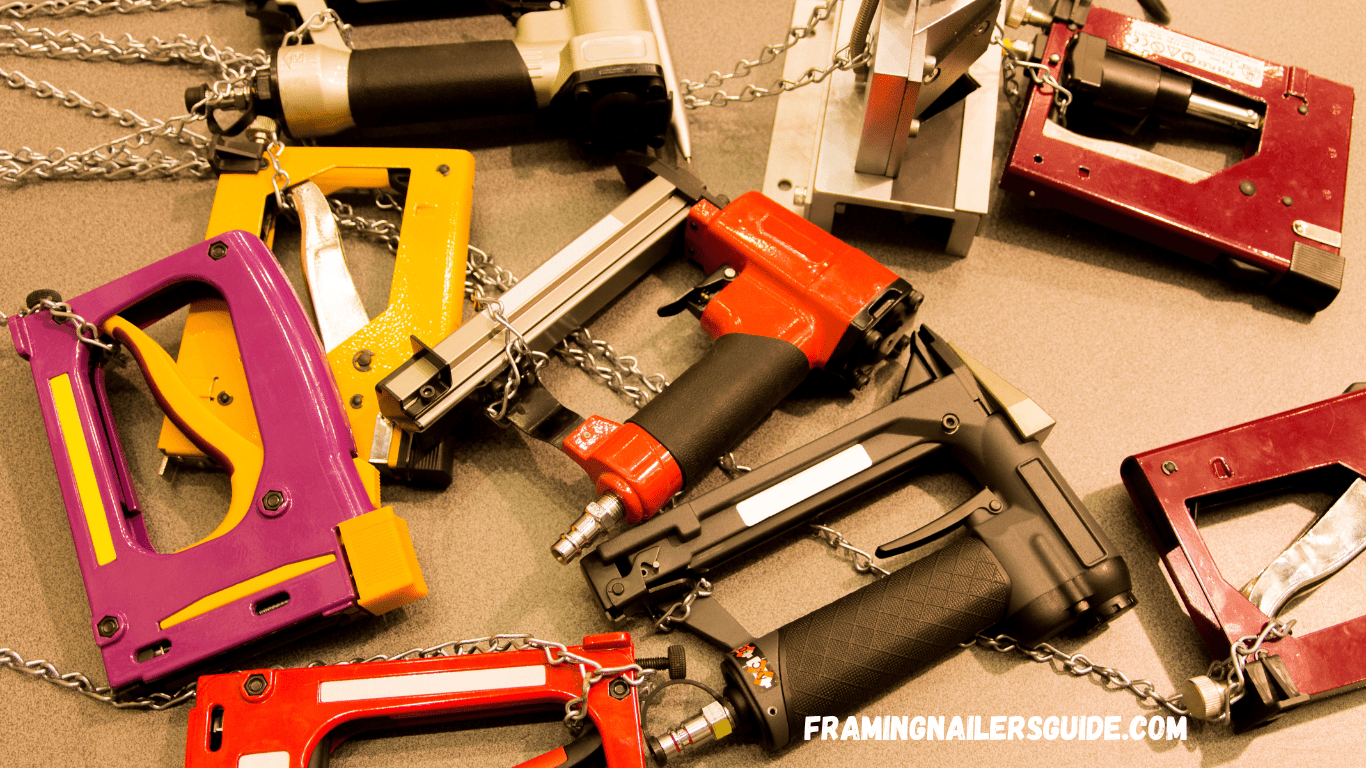

Types of Pneumatic Tools

There are several different types of pneumatic tools depending on the task. Here are a few of the most commonly used pneumatic tools:

Impact Wrenches

To quickly and efficiently tighten or loosen bolts, impact wrenches are used. They are often used in auto shops for automotive work, including tire changes and ensuring vehicle or other machinery components fit together. Using compressed air propulsion, these tools provide maximum torque output with minimum user effort.

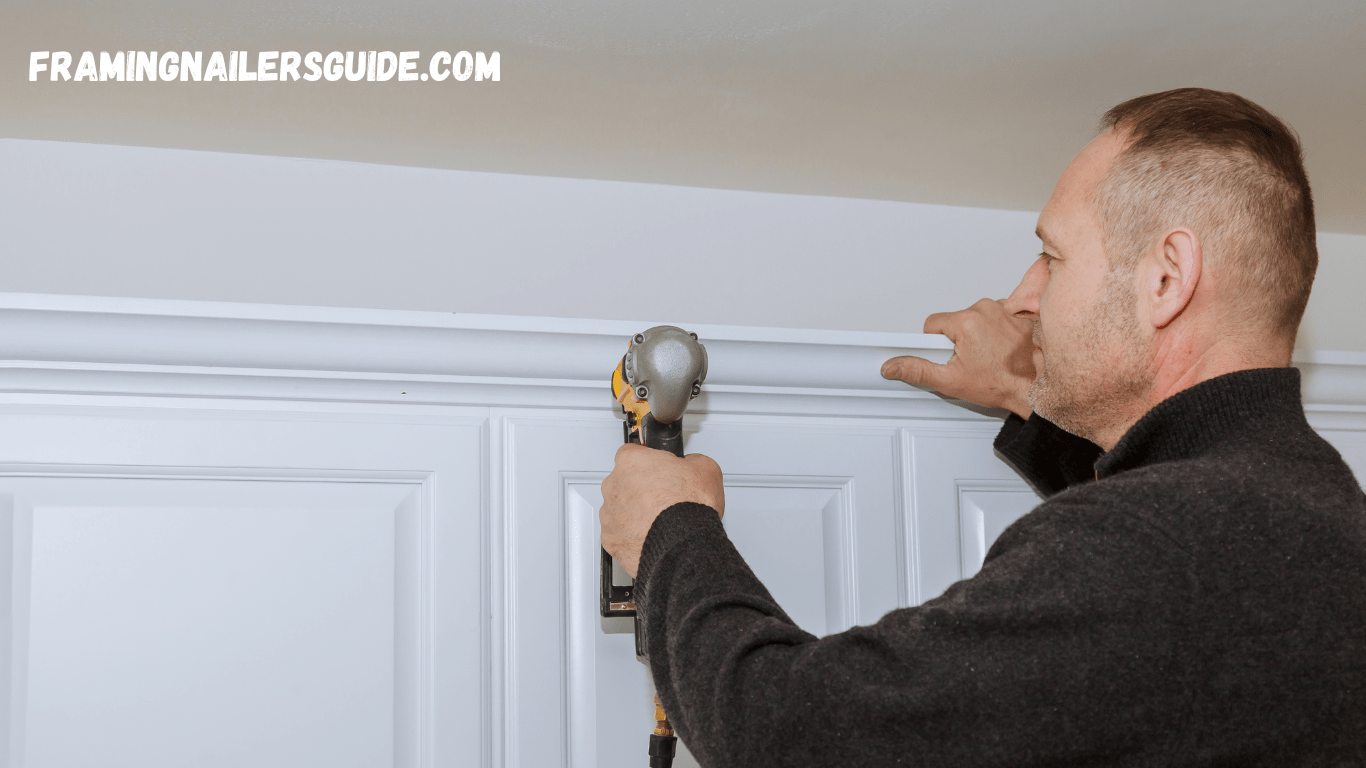

Nail Guns

If hanging things on your wall is a sport, nail guns win every time. Decking out or framing in — it doesn’t really matter what you are working on, a pneumatic nail gun will save time and effort. These tools shoot nails — via compressed air — into wood and other surfaces.

Sanders

Pneumatic sanders are suitable for smoothing surfaces and prepping surfaces for paint or other finishing. These are often used in woodwork and automobile refinishing. Pneumatic Sanders help you attain uniform and clean surface finish in lesser time as compared to manual sanding.

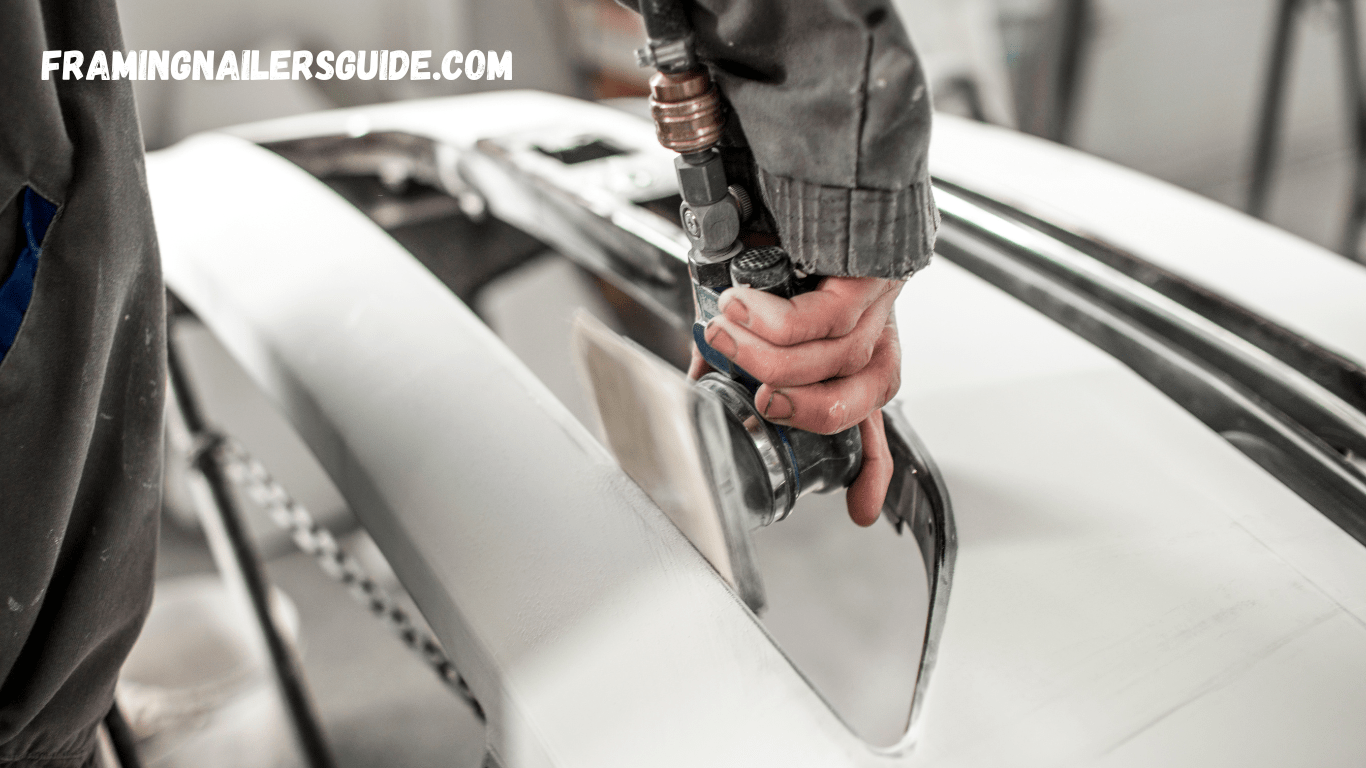

Spray Guns

Pneumatic spray guns deliver a smooth finish for painting and finishing applications. They are heavily used from automotive painting to home improvements. They work on the principle of decanting using compressed air to atomize paint.

How Pneumatic Tools Work?

The working mechanism of pneumatic tools is simple but effective. Compressed air enters the tool and instantly creates pressure that activates components inside, resulting in mechanical motion. Depending on the design of a tool, this motion is captured to do different things.

As an example, in an impact wrench, the compressed air rotates a hammer mechanism to deliver torque for fastening or loosening bolts. A nail gun uses air pressure to force a piston that drives nails into surfaces with great power and precision.

The main benefit of pneumatic tools is that they can offer a lot of power without running into bulky, heavy motors or complicated electronics. Hence, it makes them light weight, long-lasting and lastly pretty easy to maintain.

Key Sections and Functions of Pneumatic Instruments

Knowledge of some basic components and functions of pneumatic tools is important in order to understand how they work. Here’s a closer look:

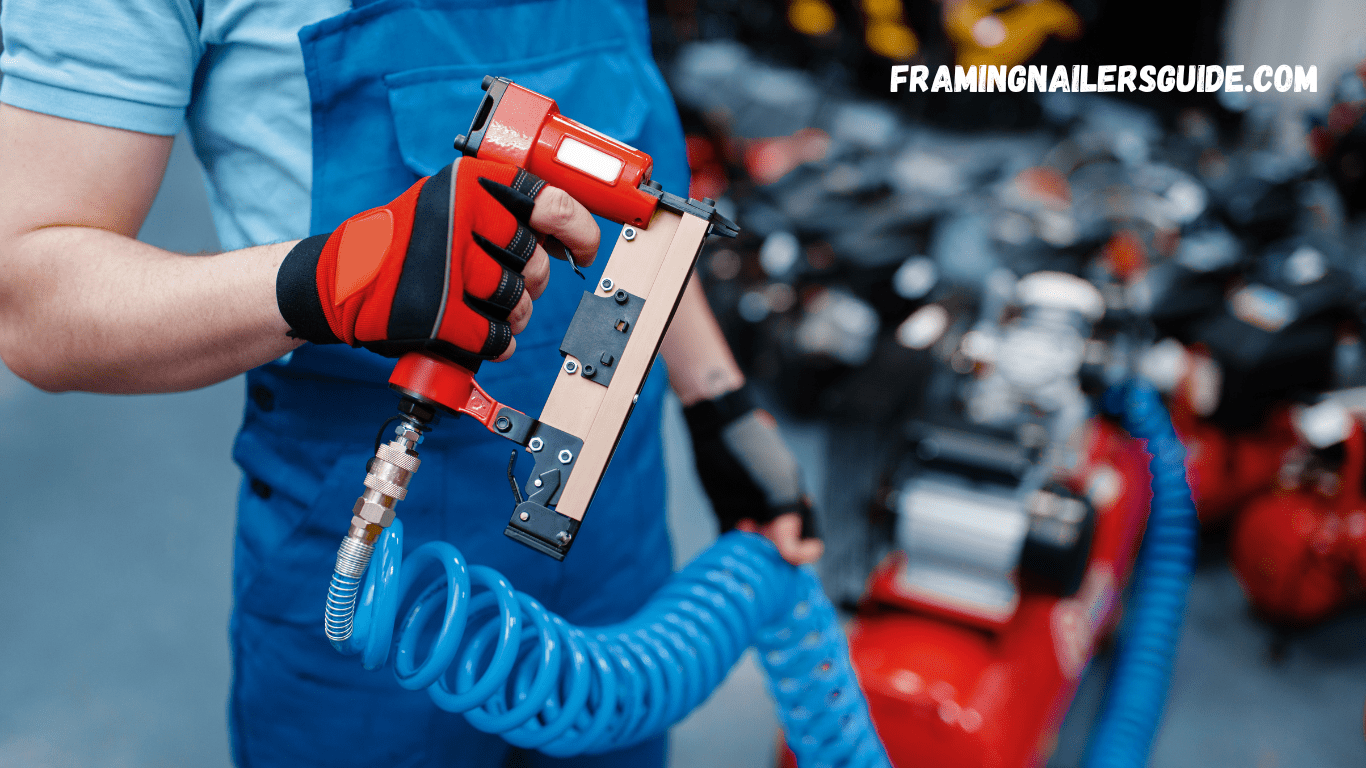

Air Compressor

A pneumatic system always has an air compressor by its side to turn the heart of it. It produces the compressed air and stores it so that it can be used to power the tools. Compressors also have different sizes and capacities, so you can pick the one according to your needs. At home you might get away with a portable air compressor and for larger industrial setups you will need to use a stationary unit.

Air Line

Air line is the flexible tubing that connects an air compressor to a pneumatic tool. It allows the tool to function by transporting the compressed air from its source. You also need to pick an air line compatible with the output pressure of your compressor, as only then will it work correctly with whatever equipment you’re planning to use.

Pneumatic Motor

One key element is the pneumatic motor, which turns energy from compressed air into mechanical motion. Depending on how the tool is supposed to work, different types of motors are used. For instance, drills and grinders typically feature rotary motors while nail guns and impact wrenches are designed with reciprocating motors.

Attachments and Fittings

Connect pneumatic tool to air line — Attachments & fittings They make sure that a secure and leak proof connection is created, so that the tool can perform its best. They are primarily used in quick-connect fittings to quickly swap out one tool for another.

How to Select Compressor Types and Power Save?

Getting the most of your air tools starts with how well you select your air compressor. Here’s what to consider:

Consider Your Power Needs

Assess how powerful the tools you plan to use will be. Each tool uses air at a different rate, and minutes per cubed foot (CFM) Make sure that your compressor is capable of supplying the correct CFM at the necessary pressure (measured in pounds per square inch or PSI).

Portable vs. Stationary

Determine if you need your compressor to be portable or stationary Portable compressors are convenient for DIY and small jobs, as making the compressor mobile is a cinch. Stationary units work best for industrial applications that call for continuous use.

Oil-Free vs. Oil-Lubricated

Oil-free vs oil-lubricated compressors. Oil-less or oil-free versions can handle less work, but are easier to maintain. On the other hand, Compressors with oil lubricant compressor are design much durable as they can hold more load so it is suits best for heavy duty works.

Popular Uses of Pneumatic Tools in Various Industries

Due to the ease of handling and use, pneumatic tools are highly successful in various industries. Here are some common uses:

Automotive Industry

Pneumatic tools are a common sight in any automotive repair shop. For example, mechanics use impact wrenches to replace tires, air sanders for bodywork, and spray guns for painting. Pneumatic tools are extremely powerful and accurate, making them the ideal choice for most automotive maintenance and repair tasks.

Construction

Pneumatic tools help make quick work of all your construction jobs (framing, roofing to finish). From nail guns and staplers that reduce the time and sweat needed on building sites to jack hammers driven by compressed air that make light work of tearing through concrete and rock.

Woodworking

One of the reason Woodworkers love pneumatic tools is because they are accurate. Air-powered Sanders, nail guns, and chisels are critical in the production of furniture, cabinetry and ornamental creation.

Workplace Safety Tips for Pneumatic Tools

Working with pneumatic tools requires a high-level of safety. Some most important safety tips to consider:

Use of Personal Protective Equipment (PPE)

Wear PPE; safety goggles, hearing protection, gloves, etc. Since pneumatic tools can be loud and also shoot debris, you want to protect yourself.

Check for Leaks

Air lines and fittings should be checked frequently for leaks. When a tool has leak in it, it can become less efficient and unsafe to use. Check that every connection is secured before use.

Stick to Manufacturer Specifications

Follow manufacturer guidelines for tool use and maintenance. With proper use and maintenance, you will increase the life of your tools and avoid accidents.

Why Choose Pneumatic Tools? Benefits Over Electric Tools

Below are the benefits of pneumatic tools over their electric counterparts, making them a common tool choice for many professionals and enthusiasts:

Lightweight and Portable

Often pneumatic tools are lighter weight than electric tools, which lead to less fatigue of the user during long use periods. Because of this, they can also easily navigate more confined areas.

High Torque and Power

Air tools provide high levels of torque and power, which is ideal for heavy-duty jobs. They perform reliably under harsh conditions.

Durability and Reliability

Because they have far fewer complicated components, pneumatic tools are durable, reliable and require very little maintenance. They are also more resistant to overheating as well as electrical failures.

Frequently Asked Questions

Pneumatic tools get their power from?

Pneumatic tools use air compression as their power supply mode, and an air compressor provides air pressure. The air compressor fills and expels donut-shaped compressed air, referred to as the doughnut effect when it comes to powering the tool.

What is pneumatic equipment?

Pneumatic equipment or rather pneumatic tools are a type of powered tool driven by compressed air. Industrial power tools — This represents mechanical essential equipment like drills, nail guns, grinders to name a few as well in addition to systems utilized in manufacturing or automation.

Who makes Chicago pneumatic tools?

Chicago Pneumatic is a company that manufactures quality pneumatic tools. With a broad selection of tools for automotive, construction, and industrial applications

Pneumatic Tools vs Electric Which Is Right for You?

When deciding between your pneumatic and electric, consider what you plan on using them for. While pneumatic tools are powerful for high-torque situations and robust, electric is very convenient due to portability and ease of use.

Pneumatic Tools: Good in the Shop Where There Is Compressed Air But in case you are looking for a tool that takes care of on-the-go tasks or exterior initiatives, electrical tools could also be extra doable.

In Conclusion

Pneumatic tools are a great tool in your arsenal whether you’re a DIY enthusiast, woodworker or automotive professional. These reasons make them powerful, flexible and reliable tools for many applications. By using pneumatic tools properly and picking the correct gear, you stand to obtain maximum performance and some great outcomes for your projects.

Pneumatic tools deliver the performance you need to complete a home improvement or professional job. Learn more about pneumatic tools and their advantages by reading our related articles Electric vs Pneumatic Tools, How to Pick the Right Air Compressor, and DIY Safety.

So to recap: by having the right tools and knowledge at your disposal, you can become the pro that you always were meant to be. Happy crafting and building!