Table of Contents

Last Updated on March 3, 2021 by John Patterson

Have you a door in your room that makes a sound every time you open or close it? Or does a toy of your little kids is not functioning and grinding to a halt? Then lubricant is a must-have item for you.

If you want to remove these problems by yourself, then the obvious solution is to go with lubricants. The general function of a lubricant is to reduce friction. But there have some differences among the lubricants. Some works differently or some may have extra features.

It’s natural that you won’t know all the things at a time. So here I am going to introduce you to a different type of lubricant, stay here with me.

What is a lubricant?

First, you should know what a lubricant is. In a general sense, the lubricant is something that reduces the friction between surfaces. A lubricant also acts as a film between solid surfaces and here it reduces heat and wears between the surfaces.

One can apply it before causing any problem in the joints of objects for preventing friction. After applying it, the machine or toy parts will move smoothly and won’t make any noise. Moving parts of cars will also get the benefit if you use a lubricant. But for that reason, you should know much and consult how to do it.

Types of lubricants and uses

There are a few types of lubricants. The uses of these are given below:

#1. Oils:

Long polymer chains create oil, and it is a thin liquid. There have additives with it to make sure of the extra properties. Some functions of the additives are –

- Keeps it from oxidizing

- Corrosion inhibitors help to prevent corroding

- Detergents ensure maintaining deposits from forming

Oil is hard to squeeze out, and that is the reason for forming slippery barriers between surfaces. The weight is less, the thinner will be it. And it will flow smoothly. There are different types of oil such as synthetic air compressor oil, motor oil, sewing machine oil, bar-chain oil, and so on.

Oil Uses

- You can use it in hinges, bearings, and for tool maintenance.

- Also can use it for sharpening the blade.

- If you want to lubricate something and avoid resistance, then use oil.

- For wicking into a small piece, use that lubricant. Don’t need to take any part apart.

You should not apply oil if the surface is exposed to dust or dirt because that can gum up and eventually cause more friction. Keep things around the surfaces when applying it. Otherwise, it can drip and run as the viscosity of the oil is low.

#2. Greases:

Generally, mineral oils are used for making grease, and thickeners like lithium base soaps are here with grease. Graphite, molybdenum disulfide, Polytetrafluoroethylene are some lubricating particles present in grease.

Lubricating properties of the oil are present in grease with stickiness. It adheres to the surface. The advantage of using grease is it protects from contaminants that may cause damage and happen corrosion.

Consistency has different ranges; some greases are ketchup thin, some are thick as like cheddar cheese. These are several types of greases – dielectric grease, white lithium grease, silicone grease, and marine grease, and so on.

Grease Uses

- You can use it in gears, bearings, chains, and linkages.

- If you need to stick lubricant on surfaces for a long time, then you need to choose a decent grease.

- For sealing out water and dust like contaminants, go with grease.

- Where there needs to put oil frequently, you can apply grease, and that will give you a great result.

- If you have guns, you should use top-quality gun grease.

Avoid using thick grease if yours is a fast-moving mechanism because that can cause too much resistance. Some parts of machines fling grease when moving. So you can avoid those parts as they can create a mess.

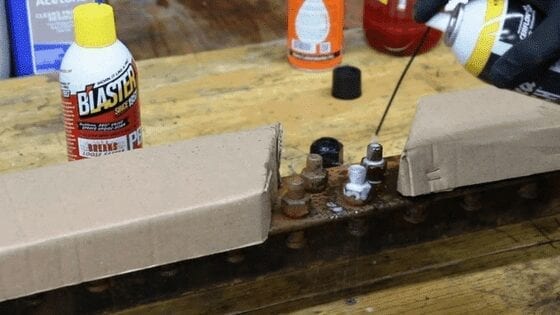

#3. Penetrating lubricants:

These are like a particular section of lubricants in the world of lubricants. These are the savior of stuck bolt combatants, can remove years of rust in a few minutes. Penetrating lubricants have low viscosity, and these are not long-lasting ones.

The only particular purpose of that is infiltrating the little cracks between surfaces, adding lubrication, and then breaking up rust. As like as oil and grease, there are many types of penetrating lubricants. But one news will make you happy that you can make low-cost penetrating oil that will perform like the others.

In research, it is found that vegetable oil and acetone mixture works like WD-40 which can apply to loosening the stuck bolt. 90% of vegetable oil and 10% of acetone can create a lubricant, but you have to be careful when doing this job.

Penetrating lubricants Uses

- It can lose any stuck bolt when you can’t make it happen with other tools or lubricants.

- Rust is a big problem for machines, and you can remove it just by applying it. It will take only a few minutes to remove the rust.

- It can infiltrate little cracks between surfaces.

- It is light lubrication that will give you a long-lasting solution.

#4. Dry lubricants:

It is made of lubricating particle-like graphite, molybdenum disulfide, and silicone. Sometimes PTFE (polytetrafluoroethylene) is also used as a lubricating particle. A feature of dry lubricants is it is super slippery.

So it is best for reducing friction between surfaces. You will commonly find this lubricant in the spray form, and here water, alcohol, and other solvents are the mixtures with it. After applying, it will evaporate, and there will be a thin film of dry lubricant on the surface.

There are also several types – graphite powder or spray, silicone spray, molybdenum disulfide spray. There is also PTFE spray.

Dry lubricants Uses

- You can use it in 3D printer rails and threaded rods. I also can apply it to locks and hinges.

- If you don’t want to attract dust or debris, then use it. Again tiny parts are suitable to apply.

- At high heat or pressure, oil can oxidize. So there you can use good dry lubricants.

- For keeping the surroundings clean, you can use this lubricant.

- You should avoid liquid-exposing surfaces because those can wash them away.

Frequently Asked Questions

#1. Is WD-40 lubricant is good enough?

Answer: WD-40 is a dust dissolving lubricant. It is a good one if you want to use it for rust removal.

#2. Which lubricant is the best for plastic?

Answer: Silicone oil is super slippery, so it provides an excellent job on plastic, also on locks and hinges.

#3. Is silicone spray is as same as WD-40?

Answer: WD-40 is waterproof and protects metal and non-metal surfaces. Silicone spray dries fast and doesn’t attract dust.

#4. Where can you use lithium grease?

Answer: Lithium grease is well to metal as is non-corrosive. It provides a good result under heavy loads. This grease has good temperature tolerance.

Final Words

If you are working with any machines, then you have to face problems regarding friction. Not only this, doors and windows also have this kind of problem. So, as these problems are so frequent, you will need to use a lubricant.

After going through the whole article, I hope now you have come to know about the type of lubricants. So if you are facing this kind of problem, now you know which lubricant you should use there.

Related To You:

#1. Pneumatic Air Tools Oil