Table of Contents

FramingNailersGuide is reader-supported. If you buy an item through the links on this site, we may earn a small commission at no extra cost to you. Learn more

Last Updated on April 16, 2024 by John Patterson

As we know there are different types of saws are available on the market in 2024.

Do you know all types of saws and their uses, I am sure you don’t?

If you want to have a collection of cutting tools, then include various types in the collection.

People have been using saws for thousands of years, and even if many technologies have arrived in the market, the saw has kept its demand as before.

You can keep from coping saw to the hacksaw in your toolbox, even more than one of the same kind.

With the shape of the saw and teeth, one has a function that is different from another.

So here I am introducing you to different types of saws and their uses, stay here with me.

Watch the below video to know what saw types you need for which job.

Pictures of Saws with Names

Here are the different types of saws with pictures.

Types of saws and their uses: Different Types of Hand Saws

Description of the different types of hand saws with pictures and their uses and benefits are given below:

#1. Back Saw:

A back saw is a hand saw. A back saw is relatively smaller than other types of saws, and the blade is narrow. As its name, it reinforced along the top edge. The common use of back saw is with miter boxes.

When there is a need for fine and straight cuts consistently, the back is too effective for that purpose. Depending on region and design, people also gave its name as miter saws or tenon saws. For 45 degrees and 90 degrees cutting corners, one can use miter saws or back saws.

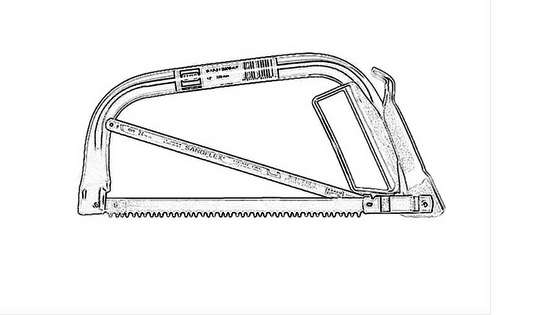

#2. Bow Saw:

Bow saw is also a hand saw. Which looks like a bow? It is one kind of bow saw which has a relatively long blade. It is preferable to use a bow saw outside of the home than inside. The blade has crosscut teeth to remove materials when you are pushing or pulling.

These types of hand saws have numerous applications outside the home. You can use these types of saws for trimming trees, pruning, cutting logs, etc. But you can also use these for other rough cuts.

Making both curved and straight cuts can be made with a bow saw. People also know these saw as Finn saws, swede saws, and buck saws.

#3. Coping Saw:

Coping saw is one of the many types of hand saws. D-shaped frame holds a thin blade in the coping saw. It looks simple much useful. You can cut both wood and metal using this saw, and it has different types of blades.

The most feasible feature of the coping saw is, you can remove and insert the blade when it is necessary to use other types of blades.

For cutting curves, molding, joining this saw is useful. Works require precision and intricate cuts going to need this cutting tool. One can also use these for trim work and scrolling.

#4. Crosscut Saw:

Crosscut saws are very useful types of hand saws. For cutting wood perpendicular to the grain, the crosscut saw works better.it has a thick blade for rough-cutting wood and has large, beveled teeth.

Crosscut saw has both small and large sizes which vary with the nature of the work.

Choose a small one for use in precision woodworking and a large one for coarse woodwork. These are the oldest types of hand saws that the ancient nations use. It is a great saw for camping and the job site.

#5. Fret Saw:

Especially for cutting tight curves, you are going to need a fret saw. It is one of the types of hand saws. Even though the coping saw is one kind of fret saw but fret saw can perform more delicate cuts. If you are to make tighter radii, select this saw.

You can make intricate cuts in the woods using it. The frame of this saw is deep (10 to 20 inches) and has a short 5 inches’ blade. Rotating the blade will not be possible for you. For allowing a much tighter cut, there may have 32 teeth every inch. The blade of it is more fragile than the coping saw.

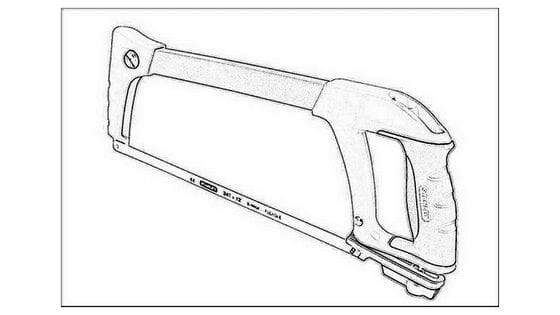

#6. Hacksaw:

Hacksaw is one of the most common types of saws, and a hand saw. These types of hand saws are lightweight, and you can use these types of saws in versatile cases- any material such as metal, plastic, wood as well as other materials.

The frame is a C frame, and the fine-toothed blade is tensioned in it. The blade has teeth about 18 to 32 per inch. We need to take special care for cleaning when cutting aluminum because it can gum it.

Hacksaw is the Best Way to Cut Plastic.

#7. Japanese Saw:

Also called a ‘dozuki‘ and the use is in Japanese carpentry and woodworking. Built with one single handle and has a thin and strong blade. The advantage of using it is it can reach those places where other types of saws can’t reach. The cutting will leave a thinner cut width, and it is more efficient.

There are two types of teeth in a Japanese saw. Crosscut teeth make a guide path, rip teeth help to finish the cut. But you can’t use this saw to cut hardwood which you can do easily with western saws. These are the best ones for pine and cypress-type softwood. Dozuki, ryoba, kataba are the types of Japanese saw.

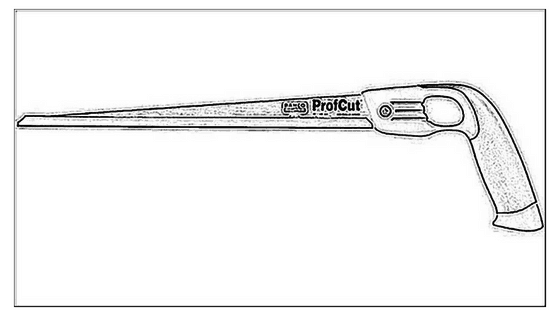

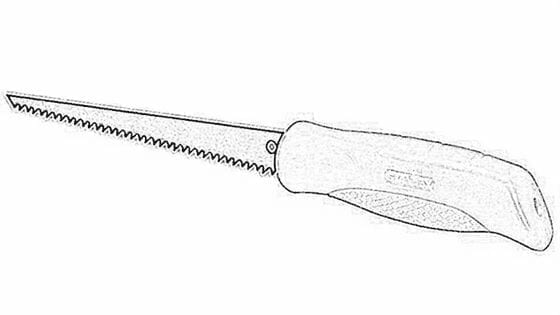

#8. Keyhole Saw:

This is another hand saw which seems like the sword of a swordfish. The other names of this saw are drywall saw, alligator saw, pad saw, jab saw. The keyhole saw has a round handle.

It is versatile even if this saw is much narrow. You can easily cut circles, curves frets using this saw, and even where other types of saws can’t work.

These are very lightweight. When you need to remove or replace a small section and where there is a possibility of damage to the interior wall because of powered tools, choose this saw. There are fixed bladed and retractable bladed keyhole saws.

#9. Pruning Saw:

The pruning saws have a pistol grip-type handle and have a 13″ to 15″ curved blade. The hand saw’s blade is wide, and the coarse teeth can be cut in both directions so that the material can remove faster.

Homeowners are the one who keeps this saw in their toolbox. But also tree surgeons, lawn services, landscapers use this tool frequently.

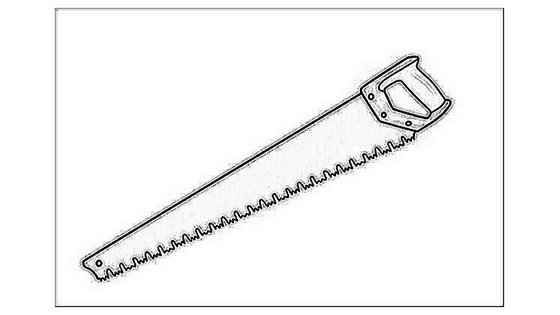

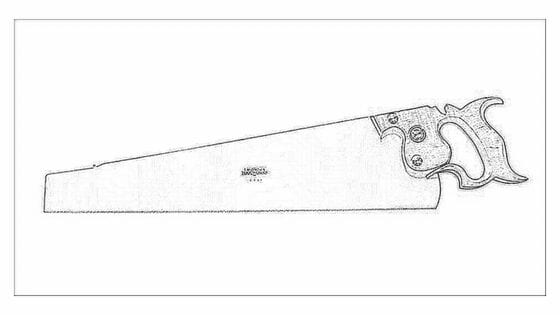

#10. Rip cut Saw:

People refer to it simply as “handsaw”. One must keep this saw if he commonly does the framing. Rip cut saw has relatively fewer teeth per inch, but these are so sharp to remove the materials. Ripsaw and crosscut saw may seem the same as you, but the difference is in their function.

It cuts wood parallel to the grain which is just opposite to the crosscut saw. The teeth are angled backward about 8 degrees when the crosscut has 15 degree angled teeth. It is like a knife that severs the fibers.

Typically, it has 5 teeth per inch. For making a finer cut, you can choose by using a rip-cut saw. Who works with wood would going to have different lengths’ rip cut wood.

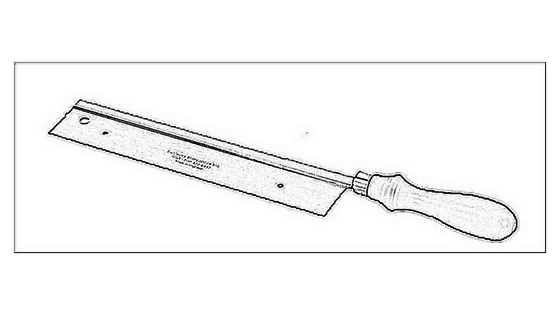

#11. Veneer Saw:

Another highly specialized hand saw. In the design of the veneer saw there has a double-edged blade that has 13 teeth per inch. The blade is about 3 to 4 inches. It is a small saw and is useful for cutting hardware veneers. The advantage of it is, you can use both edges for cutting.

For doing veneering works, it is essential to have a veneer saw. The veneer is made of fine wood. You can apply it to coarser wood which makes the panel flat. Maybe the veneer wood is thin, but the knife can’t cut it. In that case, using a veneer saw is a wise decision.

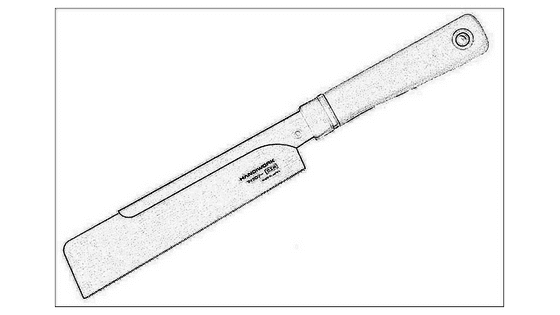

#12. Wallboard Saw:

It may seem to you similar to a keyhole saw. The wallboard saw is shorter in length but has a wider blade. Generally, there is always one edged blade in the wallboard saw, but the double-edged blade is not uncommon in the case of wallboard saw.

The blade has fewer teeth per inch than other types of saws. If you need to puncture through paneling, then this saw is fruitful. For power tools there may need a starter hole, this saw does this job well. It is a hand saw.

#13. Camping Saw/Backpacking Saw

Also called backpacking saw. As the name is related to camping, these types of saws are beneficial if you are planning for camping anywhere. This is lightweight and small, it will save your space, and for sure your luggage will not be weighty.

A camping saw is handy to clear the campsite, for getting firewood as well as for pesky prune trees from your camp yard.

#14. Wire Saw

These types of saws use metal wire or cable for cutting. The industrial wire saws are powered saws. A wire saw is similar to reciprocating saws or band saws. Engineers use this saw in the laboratories for cutting substrates, fragile crystals, and other materials.

A continuous type of wire saw is suitable for cutting walls and other big constructions. It’s also commonly used in Quarrying and mining industries for cutting hard stones into big blocks.

If you want to know about the different hand saw types with their uses, watch the video.

Types of saws and their uses: Different Types of Power Saws

In this section, we talked about electric hand saw types, electric wood saw types and added different electric saw images.

#1. A bandsaw (stationery):

It is a power saw which is tall and floor standing. There are pulleys attached to it above and below. The pulleys help to move the continuous band for cutting most materials. Fine teeth are also taken part in this job.

These types of saws are perfect for cutting curves into the wood. As well as for cutting it can cut tubes and PVC. But it has a certain limit to depth. You can cut thinner boards using it by keeping it on its edge and ripping it using a fence. But you have to have patience. Otherwise, you can cause a hamper to the task.

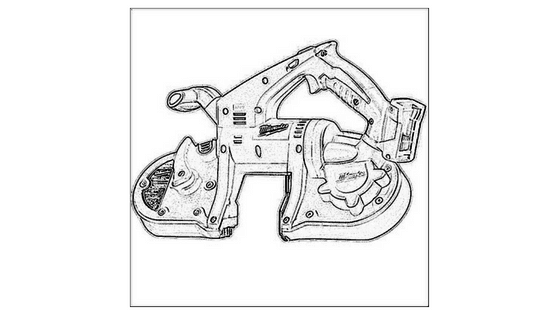

#2. A bandsaw (portable):

If you want to do the same job you did use a band saw (stationery) outside your home or another garage, take this portable band saw with you. It can do most of the jobs that its brother does and also the advantage is it has a portable facility.

You have the limitation of the pipe depth for cutting through it, typically 3 to 4-inch pipes. Give more effort to straighten the cut. For plumbers, welders, and metalworkers these types of power saws are feasible that they can move them from one place to another.

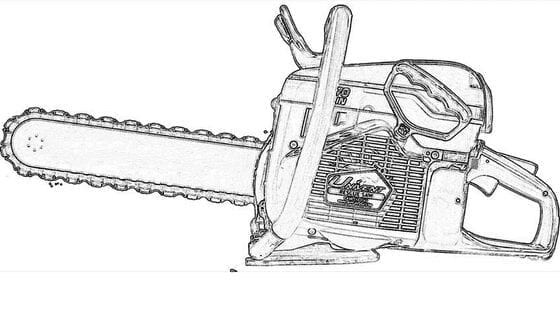

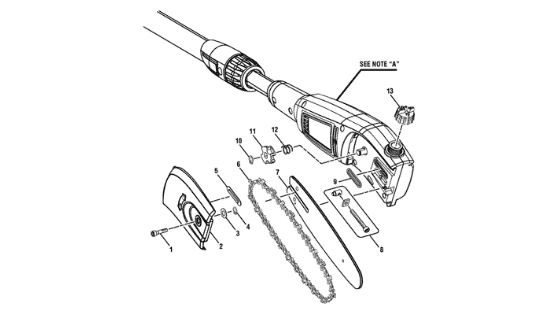

#3. Chainsaw:

A Chainsaw is another type of power saw, and a handheld band saw. As you can see from the name, you can have an idea that there is a chain attached to it. It has a linked chain with specially designed ripping teeth. For heavy-duty works, chainsaw takes part hugely.

The most common use of these types of power saws is in cutting the tree and brush. Most of the types of electric saws have two stroked combustion engines. These types of electric saws are very loud and powerful. The electric chainsaw is also in use nowadays. Depending on the region, homeowners also keep this tool in the collection.

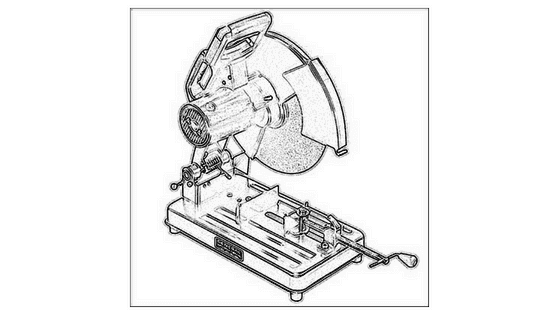

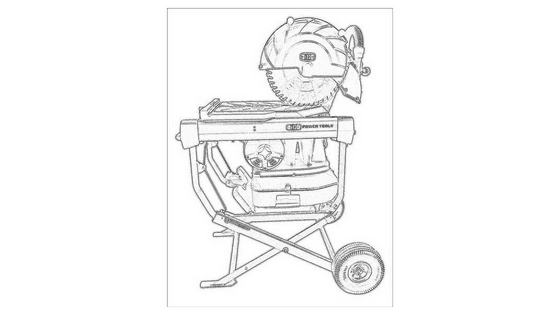

#4. Chop Saw:

It is one of the largest types of saws that have portability. It is the portable version of circular saws. There are two versions of the chop saw: one is metal and another is a masonry cutting version.

The water line is connected to the concrete cutting saw for reducing the dust. The blade has not, but it has a design of special abrasive for cutting the materials. There have three names for this saw: 1. Cut-off saw 2. Concrete saw 3. Abrasive saw.

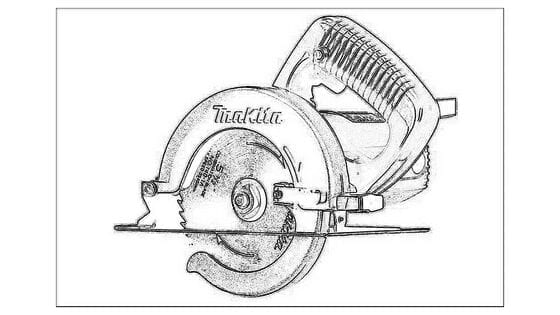

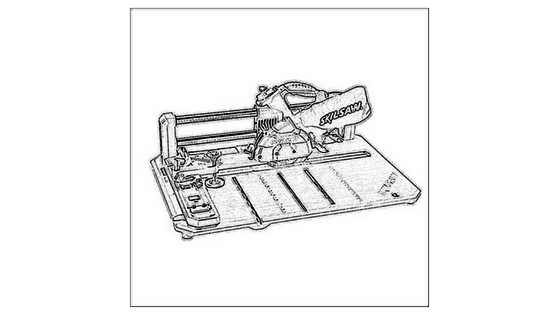

#5. Circular Saw:

Circular saw has a popular brand name, Skilsaw. It is also a type of power saw. The blade has teeth that are 7 ¼ to 9 inches in diameter. These are the most common types of saws and can cut wood, metal, plastic, and many more.

The electric circular saw has two types: worm drive and sidewinder. Sidewinders weigh, and torque is less than worm drive saw. The motion is rotational which helps it to cut. There are different types of blades that you can use to cross-cut when needing it, again for rip cut if you want it.

Using a lever, you can fix the height of the blade. For adjusting the height move the shoe to the upward or downward direction and then lock the blade. But there is a limitation in the depth you should keep in mind.

#6. Flooring Saw:

A flooring saw is a portable power saw. Like the name, it is used to re-saw flooring to fit. The materials may be hardwood, bamboo, or laminate. It is a specialized one that can replace the table saw, miter saws, and other tools that you need to cut flooring.

The biggest advantage is that it can save a lot of time of yours as you don’t have to move materials from one room to another or from the garage and vice versa.

And that way you can save your strength too. Not only flooring saw, but you will also find a few top-quality flooring nailers on the market in 2024.

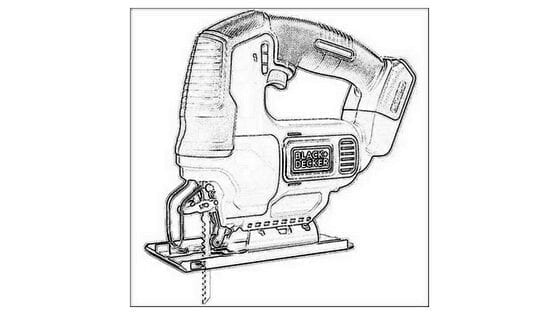

#7. Jigsaw:

It is a handheld power saw. Probably the most powerful saw with a reciprocating blade. You can use it for cutting metal sheets and custom-shaped plywood.

Manufacturers also name it sabre saw or bayonet saw. The blade has fine teeth which you can move up and down at different speeds.

Jigsaw has a special design to cut curves and no- straight lines. When cutting the curve, don’t apply force over it because of the force there may be an uneven cut.

The blade is small, so it is a weak one to apply force to the blade when cutting. In that case, steer the blade. Again your force can break the blade.

Another point is that controlling is a problem when working with a jigsaw. Better look for a long cord or cordless jigsaw in the market.

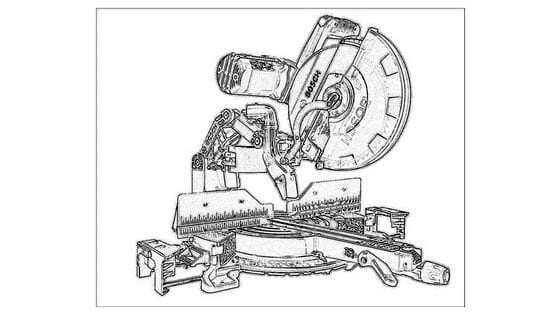

#8. Miter Saws:

For precise measurement, you can use miter saws undoubtedly. It is an electric saw with multi-function. People use that tool for cutting wood perpendicular to the grain, for miter cuts, and when it needs to cut across the thickness of a sheet or board.

Again you can use this for mixing of bevel and miter cut. But first, before every job you have to fix the miter saws.

A blade is an important part of the miter saws. However, even for the expert, choosing a good miter saw blade can be a huge task. There are different sizes, different brands, and several materials to choose from. You will also have to think about the number of teeth you need to get the precise cut.

These types of saws have high degrees of accuracy, that’s why you can use these for wooden frames and molding. For rip cuts, you cannot use this saw. Also, you can use this injunction of tables.

#8.1. Compound Miter Saws:

For making straight, miter as well as compound cuts, have the compound miter saws. It is a miter saw on steroids and a power saw. For adjusting multiple angles, the blade is placed on an arm.

This mechanism also utilizes complex scrollwork and trim. If you want to trim out the window and add crown molding, nothing but compound, miter saws can save your time other than any type of electric saws.

#8.2. Standard miter saws:

It is the simplest version of all types of miter saws. The cutting capacity is between -45 to +45 degrees. These types of electric saws are perfect for making miter cuts. You can use these easily and quickly.

The lightweight of the saws provides you, and you can carry them anywhere. You will be the beneficiary of the price also. At an affordable price, they provide you with stable functions compared to the other miter saws.

#8.3. Sliding compound miter saws:

The arms of the sliding compound miter saws are not fixed in place which is the advantage of using them rather than the previous two. The blade can move in out along with up and down.

The sliding compound type can have a double or triple cutting capacity. These are the most expensive types of saws as they have more luxurious features. Extra cutting is possible with the saws. And of course, it is likely to do miter and bevel cuts.

10-inch vs 12-inch miter saws

Sometimes the question may arise as that which miter saws you should buy, 10-inch or 12-inch. So here is some information about these:

10-inch:

The blades have a smaller radius, so the spin and the pace will be more. You’ll need less time for the work done. For 10-inch miter saws, you will need fewer teeth on the blade. 10-inch saws are portable, so you can quickly do your job outside the workplace.

12-inch:

With the increasing size, the power will be more, so you can quickly do larger projects using this. It is more durable because of its size and rugged nature. The cost may be higher than the 10-inch saws. It is best for harder materials; you can cut 4x6s with one pass.

#9. Radial Arm Saw:

There is a cutting table where there have an extended motor and blade placed. It is a power saw. One can easily make compound cuts, miter cuts, etc. using this tool. If you want, you can interchange the blades of a radial arm saw and a circular saw.

At first, verify the speed of the spin. When you slide the arm, it pulls the blade across the material. These are best for cutting long pieces of material, especially wood. One can easily use this tool for crosscutting.

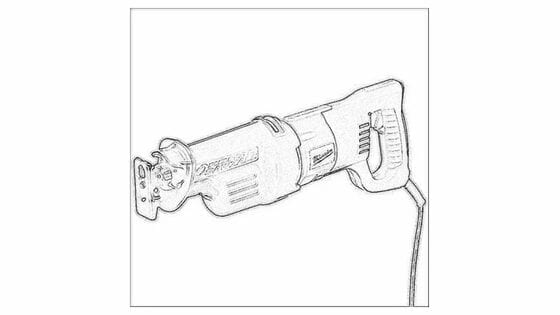

#10. Reciprocating Saw:

Like the jigsaw, you can move the blade of the reciprocating saw back and forth much quicker. It has a reciprocating blade which people call Sawzall. The blade is parallel. Easily you can cut woods, drywall, pipes, and many more using this saw.

Also, you can cut beneath walls and wood joints using it because the parallel blade can cut nails and wood. It is an invaluable saw for demolition work. Best Cordless Reciprocating saw has fineness lacking.

#11. Rotary Saw:

Rotary saws have a screwdriver-type handle which is small. The blade here is fixed with it. While you need access or repair a wall, then do it with a rotary saw because in these cases it is the ideal one. Workers use it for crafts for construction frequently.

It is effective for drywall, paneling, and other small cutting tasks like a keyhole saw. The saw resembles a drill. If you don’t want any pilot hole in the wall, this is going to do the task well.

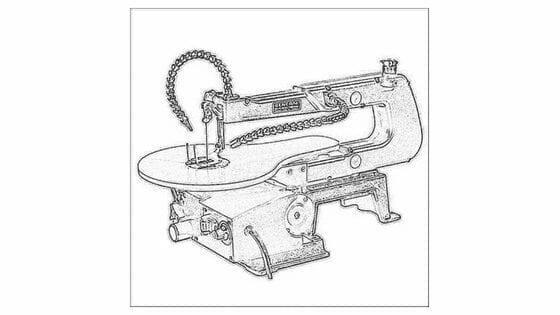

#12. Scroll Saw:

At first glance, you may confuse the scroll saw with a sewing machine. Even some scroll saws are pedal operated. One can operate it with a band, and even a continuous or reciprocating blade.

The power saw’s features are similar to coping saws. It will suit you well for making the intricate curved cut. It is a type of band saw as it combines the functions of a coping saw and jigsaw.

The saw allows you to make interior cuts and there will be no entry point. There is a table with the scroll saw where you could lay a material and achieve precise rotation. These are best for creating curves with edges. Spinal lines or patterns can be done with the benefit of a table.

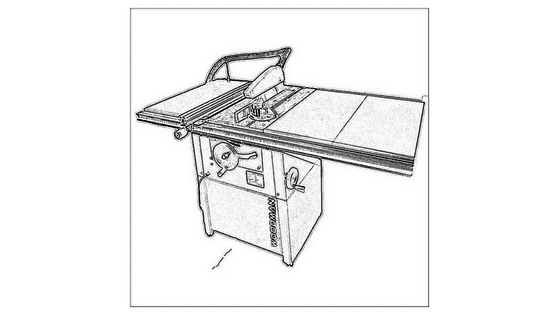

#13. Table Saw:

A table saw is a little larger than a circular saw. The combination is a blade on an arbor that is set on a table. The table supports the material which you will cut and the blade comes from under the table. As the blade is exposed so if you are not alert then you can hurt yourself.

You can control how much of the blade you want to expose. Thus, you can adjust the depth to cut. There are safety features in modern table saws like dust extractors, magnetic feather boards.

When there’s no necessity of exposing the blade so much, then by reducing the height you can avoid injury. For making numerous rip cuts identically sized pieces, table saws are great.

If you want to know the difference between the miter saws and table saws, we think this article will help you.

#13.1. Benchtop

These types of saws are so light and compacted. For the light-duty of work, these are best to use, and workers will prefer this in this regard. They do not have any wheels for transportation, but as these are lightweight, you can carry them anywhere. Plastic, aluminum, and other lightweight materials you can cut using these types of saws.

Benchtop table saw have some disadvantages like limited, rip capacity, smaller tables. But for cutting plywood or light materials why go with the expensive ones when you have a benchtop. Avoid working with material sheets.

#13.2. Jobsite

Jobsite is quite famous among contractors who need a portable table saw. That’s why another name for it is ‘contractor table saw’. The saws are robust in their construction and give you more accurate results. Heavy-duty works can easily be handled using Jobsite as well as sturdy and durable.

The advantages are: better fences, better alignment adjustments, 24-inch rip capacity, some have an extension table. There is a stand attached to the Jobsite. The stand is a trademark because it allows folding up and taking less space. Maximum time there have wheels with the stand for portability.

#13.3. Contractor

It is the professionals’ choice table saw. These have a belt-drive, large induction motors. Better than full-size cabinet saws as they have portability. More powerful motors will be heavier; the weight maybe 200 to 300 pounds.

The outboard motor needs a longer belt which increases the vibration of contractor table saws. That’s why dust collection capacity is poor. Though there are so many new design table saws, these kept their demand high as they are less expensive than cabinet saws.

Again, it is more powerful than new models that are portable. Outboard motors in a contractor are rare, and that will be in the old models.

#13.4. Hybrid

You may have been confused about the hybrid table saws and thought about what they are actually. You saw outboard motors in the contractor, but here in hybrid, there have inboard belt drive induction motors.

They are a middle ground between the old contractor and industrial cabinet saws. They have open leg stands; some models have full enclosures.

The leg increases the confusion between hybrid saws and industrial cabinet saws for the buyers. The similarities are skin deep.

#13.5. Cabinet

These are the most powerful ones among the other table saws. They are similar to cabinet-enclosed hybrid saws. Cabinet saws are durable and robust, that’s how they are designed. And can stand heavy-duty works. These are heavy, bulky but are long-lasting and precise.

Factory shops, specialized schools, and almost all professional contractors have a place for a cabinet table saw. The fences are more accurate and robust than any other saws. After making all the adjustments, you can leave it like this even for a long time.

The motors are very powerful. It can be anything; hardware, large material sheets, plywood, and others. It has little portability as its weight is nearly 500 pounds.

#14. Masonry Saw:

The most common use of the masonry saw is to cut lightweight concrete blocks. It is familiar to a standard hand saw. But both the blade and the teeth are larger than the hand saw and have a pistol grip handle.

You can remove the blade from the handle. Blades’ length is ranging from 24.6 to 27.5 inches. The saws have 1 to 3 teeth per inch in length. For carrying dust and waste material these have deep gullets. These are designed to push stroke.

#15. Oscillating Saw:

Orthopedic surgeons have been using oscillating saw sterilized versions for decades. It is a jackknife of power tools. When you need to cut within limited space, use an oscillating saw because it’s a vibrating blade is very useful in that course.

Cutting, grinding, sanding, sawing – it can handle each one of these jobs. Carpenters, contractors, flooring, and cabinet installers hugely use this tool. This tool delivers clean results. It doesn’t spray dust as it vibrates over a narrow arc.

Those oscillating saws which have a greater oscillating angle can cut faster. You can control speed as it has a variable speed trigger.

#16. Pole Saw

A saw on the end of a pole is a pole saw. The name is self-explanatory. If your pole saw is powered it will take the form of chain saws or a small powered saw. Its power source can be the main electric, battery, or gas engine (Petrol).

In a non-powered or manual action pole saw, there is a pruning saw attached to the end of the pole. If you are a tree trimming crew, these types of saws are a great benefit for you.

#17. Track Saw/Plunge Saw

When it comes to ultra-precise cuts in a straight line on a wooden object, track saws are one of the most excellent types of saws options available. It’s a modified circular saw that does the same task as the circular saw does.

But the difference between a chainsaw and a track saw is- chainsaw doesn’t go through any given guideline, and the track saw follows a specific and pre-assigned track.

The saw moves in a straight line along with the direction of the metal guide. As a benefit, you don’t have to worry about slipping or moving away from the cutting line.

To provide the guideline or track-line metal tracks are used in most of the track saws. For its uses, it’s also called plunge-cut saw or plunge saw as well.

Uses of Track Saw:

- Most of the time, track saws are used to make precise cuts like cross-cut, extended rip cut, rip cut, angular cuts, etc.

- If you have to slide down a large board made of wood, it’s best done with the help of a track saw.

- As long as you need a combo of precision and mobility, a track saw is a way out.

- For making long cuts of objects like plywood, MDF boards, OSB boards, hardboard, etc., track saws are used.

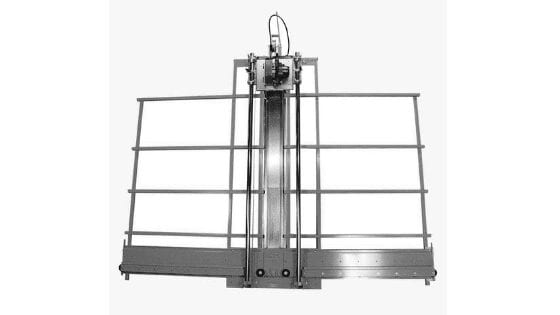

#18. Panel Saw

As you can see from the name, Panel saws are types of saws that can cut thin woods into sized parts (as for panels). These types of saws are designed for cutting large panels. It can be horizontal or vertical.

Vertical saws usually take up less floor space than horizontal ones. A horizontal panel saw is like a big table saw. A sliding feed table is attached to the saw, and it pushes the materials through the blades.

A vertical panel saw is a high and low-cost type. Panel saw is very common in sign making, cabinet making, and similar types of industry.

FAQs

Question #1: Is a chop saw and miter saw the same thing?

Answer: These are different. Chop saw can be cut in one direction. But the miter saws can spin the blade at 90 degrees.

Question #2: What is a miter saw good for?

Answer: For making a quick and accurate crosscut, cutting of molding and trim, miter saws are the best one.

Question #3. What is a compound miter saw used for?

Answer: A compound miter saw can cut both miter and bevel cuts. You can use it if you need to cut in both the left and right directions.

Question #4: Is a miter saw a circular saw?

Answer: Miter saws are not circular saws. Quality Circular saw cuts any material of any shape. Miter saws are best for crosscuts which circular saws can’t do.

Question #5: Can you use a miter saw to cut metal?

Answer: Not all the metals you can cut with miter saws. Metals like aluminum, plywood you can cut with it.

Question #6: Can you turn a circular saw into a miter saw?

Answer: Yes, you can turn a circular saw into miter saws using Portable Universal Power Station.

Question #7: Can you use a miter saw as a table saw?

Answer: You can use miter saws as a table saw by attaching a table with the surface of the saw.

Question #8: How much is a table saw?

Answer: It depends on its functions. The powerful ones will be pricier.

Question #9: How much is a miter saw?

Answer: It also depends on the functions. Generally, the miter saws are less pricey than the table saw.

Question #10: Why do I need a table saw?

Answer: If you want to do all the cuts using one saw and want to save your energy and time, then you should use a table saw.

Question #11: What can you do with a table saw?

Answer: A table saw is best for rip, crosscut, square, dado, and even miter cuts. When needing the same length cuts at a considerable amount then the best option is to use a table saw.

Question #12: What size miter saw do I need?

Answer: It depends on your use case. But the safe bet would be 10-inch miter saws instead of 12-inch.

Question #13: How to choose a miter saw?

Answer: Choosing miter saws depending on your tasks. Those who have marked scales, solid angle presets, good fence support, smooth sliding action, safe blade guard, dust collection ports, choose those miter saws.

Question #14: What to look for in a table saw?

Answer: Before buying a table saw, consider your size of work if the table saw can fulfill it or not. And look for its features.

Question #15: Can you cut aluminum with a miter saw?

Answer: Yes, you can cut aluminum with miter saws, but the cuttings may cause more wear. It may hit the dust guards.

Question #16: Why do I need a miter saw stand?

Answer: At the time of cutting a lot of wood or other materials, you need a sturdy and robust surface. That’s why the miter saws stand is useful as it can give you a stable surface.

Final Words

When you are interested in woodworking or towards the jobs where the need to use a saw, then you have to have a clear concept of different types of saws and their uses. Which saw is suitable for which task, is very important to know.

After reading this article, I think you have gained much knowledge about the types of saws and their uses. Now you can choose the one for you to use on your project.

For any suggestions, comment below.

Related Reading:

#1. Different Types of Sander with their uses