Table of Contents

- 1 What is Dielectric Grease?

- 2 Dielectric Grease Uses

- 3 Frequently Asked Questions (FAQs)

- 3.1 Question #1. Can I use dielectric grease on battery terminals?

- 3.2 Question #2. Can you use Vaseline for dielectric grease?

- 3.3 Question #3. Should I use dielectric grease on headlights?

- 3.4 Question #4. Can I use dielectric grease on electrical connections?

- 3.5 Question #5. How to use dielectric grease?

- 4 Final Words

Last Updated on April 16, 2024 by John Patterson

I found a YouTube video of an arrogant gentleman who is just misleading people with some vague information and also not getting to the point properly on the definition of dielectric grease and the use of it.

I’m not going to reveal the video link here, though.

Instead what I’m going to do is, before I tell you about use of Dielectric Grease, I’m going to give you a brief idea about dielectric grease itself.

Not interested?

Well, if you already know what dielectric grease is and only want to know about its uses, then skip the following point. Better jump to the “ Use of Dielectric Grease ” straightaway.

What is Dielectric Grease?

Dielectric grease is silicon-based grease.

If you want to know about its conductivity, it’s non-conductive and non-curing.

Once it comes out of the tube, you will see a greasy consistency, and it can remain greasy throughout its lifetime. That means it doesn’t get hard over time.

So, by definition, dielectric grease is a non-conductive gel-type substance that acts as an insulator.

Let’s talk about the use of this type of grease now. It will clear up all the confusion you still might have.

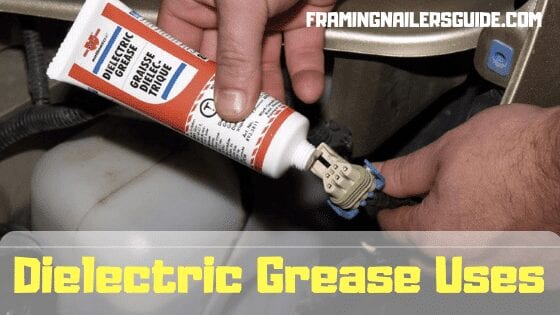

Dielectric Grease Uses

Have you ever seen any corrosion on the bulb socket connectors?

I bet you saw that.

Well, it’s quite usual that the socket won’t work if there is corrosion on the socket connectors.

It’s not only about the corrosion of bulb socket connectors.

Any bare metal tends to do a chemical reaction to the air and oxygen, which we call oxidation.

Oxidation ends up reducing the flow of electricity as its less conductive than the metal.

The reduction of electricity flow won’t create a problem if there is not a significant amount of oxidation.

Nonetheless, if you let the oxidation build up for a long, it will cause significant problems later.

It can decrease the voltage, and perhaps make some devices not working correctly.

At the highest point, it can be a cause of short circuits, sparks, and even it can lead to a fire.

Dielectric grease comes in handy to prevent all these types of arcing, corrosion, and oxidation.

As it acts as an insulator, so it prevents arcing. This can help to reduce the voltage leakage if a high voltage occurs.

Dielectric grease plays a vital role in creating a secure electrical connection to keep air and water from coming into contact with the metal.

Eventually, you are preventing short circuits and corrosion by keeping the connection from water and air, respectively.

Dielectric grease comes in handy to protect the rubber and plastic parts of the connectors too. Lubricating rubber fittings to make them more secure without fusing is another vital role that this grease plays.

As this type of grease doesn’t dissolve in most liquids, therefore it’s quite an excellent option to use for vehicles that come into touch with water too often.

So, we can summarize the dielectric grease usage in the following fashion.

- To keep water, air, dirt, salt, and other elements from the electrical connection. Eventually, this prevents arcing, corrosion, and oxidation.

- To improve electrical performance by reducing arcing and voltage drop in unfavorable weather conditions.

- Lubricating plastic and rubber.

- To prevent spark plugs from fusing to boots.

- You can apply dielectric grease to electrical panels, spark plug boots, battery terminals, light bulbs, breakers, sockets, headlamp connectors, ignition coil connectors, bulkhead connectors, trailer connectors, vehicle wiring, etc.

Frequently Asked Questions (FAQs)

Question #1. Can I use dielectric grease on battery terminals?

Answer: Yes, you can. It will prevent corrosion from happening. It keeps the acid from getting onto the metal.

Being said that proper use of the grease is essential here. Otherwise, it will cause a short battery life and hinder a good connection.

Alternatively, you can use anti-corrosion spray and silicone grease to prevent corrosion.

Question #2. Can you use Vaseline for dielectric grease?

Answer: Yes, people used to use vaseline for decades. Using vaseline or petroleum jelly is an old-school method with some downsides.

As vaseline is petroleum-based, therefore, when it gets hot, it runs. On the other hand, dielectric grease is silicon-based; hence, it doesn’t run when it gets hot.

So, when it’s about holding off high voltage over a long path dielectric grease is far better than vaseline.

As you can see, you can use vaseline, but dielectric grease is much superior to any petroleum-based substance.

Question #3. Should I use dielectric grease on headlights?

Answer: This is not necessary. Better if you avoid using dielectric grease on headlights. Yes, it will help to keep water away, but most of the excellent headlight has waterproof housing inside.

I don’t recommend using dielectric grease on headlights.

Question #4. Can I use dielectric grease on electrical connections?

Answer: Yes, you can use dielectric grease on electrical connections. In fact, you should be using dielectric grease on electrical connections to seal it properly and keep the connection from air and water.

It will eventually prevent arcing and corrosion. I’ve discussed enough on this above. I believe if you go through the “Use of Dielectric Grease” point, you will get the answer more elaborately.

Alternatively, you can use conductive grease to improve electrical connections.

Question #5. How to use dielectric grease?

Answer: It will be a whole another blog post if I want to write on how to use dielectric grease for each application.

The general rule of thumb is to use a small amount initially wherever you want to use it.

Let me generalize the guidelines here, or let’s say you are applying it in spark plug boots.

After taking a small amount of grease, coat the inside of the boot of the spark plug wire. Don’t let a lot of dielectric greases down onto the terminal inside the spark plug wire. Otherwise, get ready for some misfiring.

You can apply the grease on the spark plug body too.

In short, make sure you are not applying a large amount of grease all at once.

Final Words

I’m sure you are now quite well-known for dielectric grease use, what it is as a whole, and where to apply it.

I tried to answer some of the frequently asked questions too.

Now it’s your turn.

Don’t forget to buy quality dielectric grease from the market. Quality matters most. That’s why don’t go cheap.