Table of Contents

Last Updated on December 8, 2024 by John Patterson

If you have ever stood in the hardware aisle, staring blankly at a wall full of nails and screws wondering what to use for your latest DIY project, you are not by yourself. Nails vs screws is a debate that many a DIYers and home improvement fans have. They each have their own set of characteristics that lend themselves to particular applications. Knowing when to use each type of fastener will quickly take your projects up a notch and help them stick together for the long haul.

This blog post highlights some of the important factors that need to be considered for deciding between nails or screws. You will understand how all the fasteners perform when they are under stress, which material they suit best to as well as whether or not you need to worry about the appearance of the fasteners head.

We will also discuss different kinds of fastener other than nails and screws so that you have the full know-how of what to use, and how, for your next DIY home improvement project.

Nails vs Screws: Ultimate Stress Factor

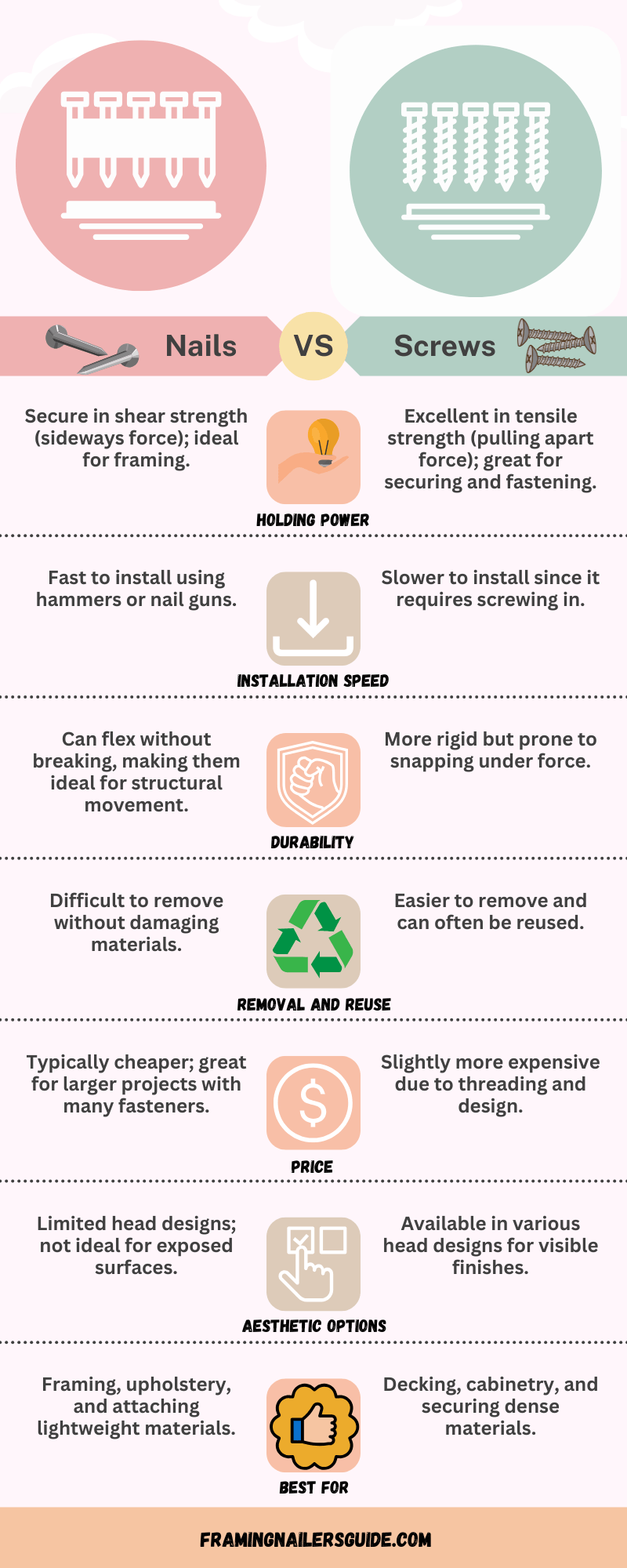

One of the most important factors to consider when deciding between nails and screws is whether the fastener will be subjected to shear or tensile stress. If shear strength (the stress resulting from forces acting in opposite directions) is more important, nails are normally better. This makes them perfect for applications in which the material may shift or move, including framing and structural applications.

Screws, however, have high tensile strength — meaning they resist being pulled apart. Because of their threaded structure, they are able to catch tightly, which makes them great for projects needing a tight grip, such as cabinetry or furniture building. When you look at screws vs nails though, their material movement and the forces they will encounter all play a role.

Neither nails nor screws were created equal and each has pros/cons when it comes to being able to withstand stress. Screws are for applications that do not just pull; like anything doing a lateral movement in stress, use nails — otherwise, the screws will just pop out of place. Knowledge of these stress factors allows you to determine which type of fastener suits each project best and will be strong and stable for a long period.

Difference Between Nails and Screw

Design

Functionality of nails and screws [Design matters] Nails are components with a smooth, and straight shaft with a flat head that is designed for quick insertion via hammer. And screws, on the other hand, have helical threads that enable them to be driven into materials using a screwdriver or drill and which offer a stronger hold.

Nails have a much simpler design, which makes nails fast to install — especially on large-scale projects. The skim shape of them will help to go through the materials quickly which really saves time and energy. But this simplicity also makes it weak when it comes to securing a joint, especially screws are better in this aspect.

Screws are more complicated in nature, with different thread pattern, length and head shape. This creates a complexity that makes screws more versatile and stronger than nails at holding things in place, as screws can be engineered for specific uses. The question of screws vs nails will ultimately depend on the various design elements and how they complement your project.

Fastening Mechanism

While long story short, grasping about how the nails holding mechanism versus screws is imperative to nail down your fastener decision! Nails use friction, and also compression, to hold materials together. When driven properly, the surrounding material squeezes around the nail and creates a friction fit to hold it in place.

In contrast, screws use their threads to dig into materials for a secure hold. These threads dig into the material when driven in, providing a pullout resistant grip. It is this mechanism that makes screws ideal for applications where high holding power is needed, like attaching hardware or load-bearing structures.

Each of them has their own benefits. Nails are great for quick assembly, usually when speed is a key concern. Screw hold-through to the sky and are preferred when accuracy and support is key. Understanding these differences will allow you to judge upon whether nails or screws are more appropriate for your project.

Holding Power

HOLDING POWER WITH NAILS AND SCREWS: A TIMELY TIP: as a rule of thumb, screws hold more strength due to their threaded form. Screws form a non–permanent type of adhesive bond that is very difficult to separate without unscrewing.

Nails are held by friction and the compression of materials. Nails are fine for many purposes but can become loose after a while, especially in materials that will be moved or vibrated. That is why screws are preferred in projects that need to hold for a long time.

Evaluate the amount of holding power that is needed when deciding on what fastener to use for your project. Screws are usually the better option for tasks that require a strong, permanent hold. But for the projects that put a premium on quickness and convenience, you may want to lean toward nails instead.

| Best for mounting hardware | Best for drywall | Less likely to split wood | Best for framing | Best for trim work | |

|---|---|---|---|---|---|

| Nails | X | X | X | ||

| Screws | X | X |

Common Types of Fasteners

From nails to screws, there are many different types of fasteners that can be used for DIY projects. Understanding such options will let you broaden your toolbox and help you confront more challenges. Below is a series of different types of fasteners:

Screws have a universal application as they can be made out of many different materials and in several sizes. The threaded design allows a solid grip, particularly on wood and metal.

Bolts are like screws but we use them mostly with nuts to hold two things. Using them is suitable for heavy-duty applications where a strong and permanent hold is needed.

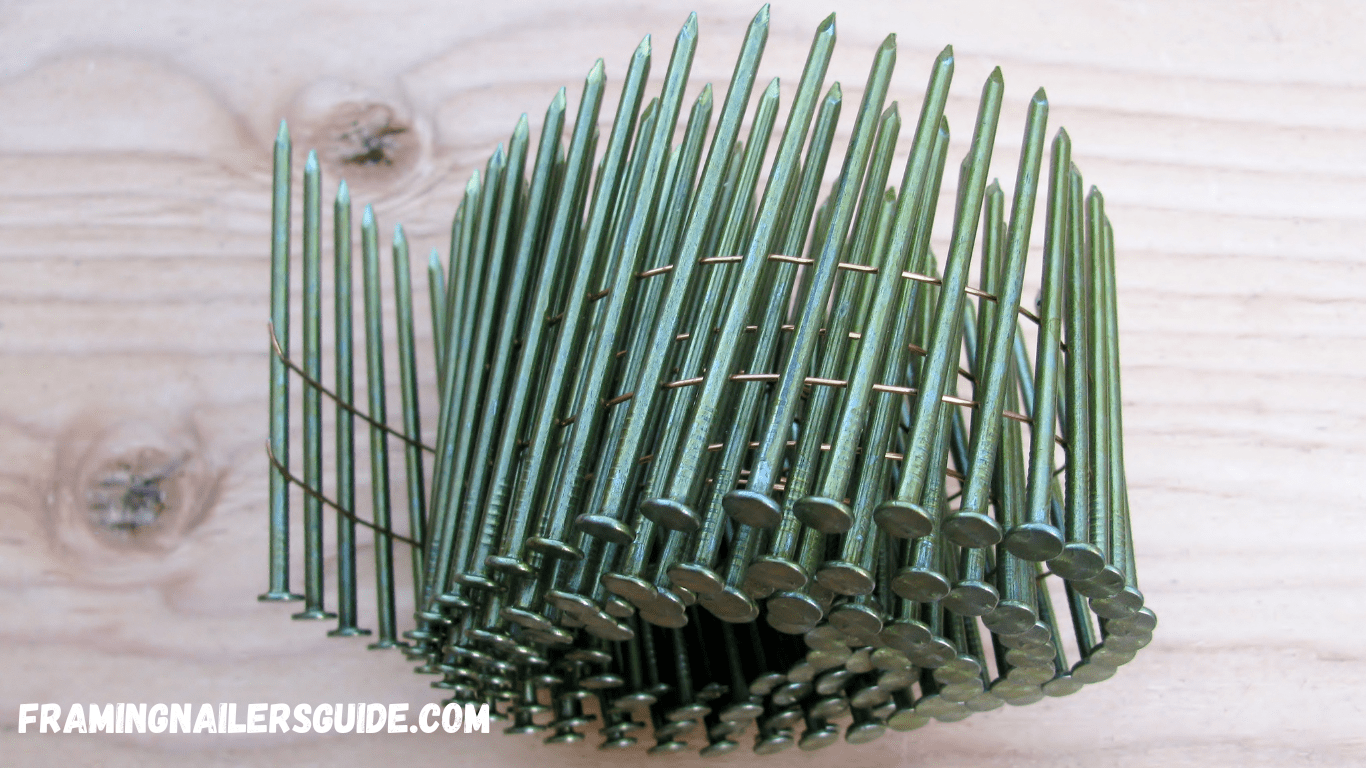

Nails affix quickly and are often used for the framing and carpentry phases of a build. The smoothness of their design makes them easy to insert quickly, and they are used for large projects.

A rivet is a permanent mechanical fastener which joins materials together. These are usually used in applications where welding is not a possible solution to use, for instance, metalwork and aircraft construction.

Wall anchors — Jigs and fixtures are connected to tough surfaces for example concrete or product. They offer a firm grip in hard substrates, expanding upon installation.

Clamps or temporary fasteners which help you hold the materials you are working with in place temporarily while they either dry or are being assembled. They are a vital part of wood and metal work.

Nuts and Washers: When bolts are used, nuts provide the same effect as a wide surface to distribute pressure, while washers keep it from loosening. They are an essential part of establishing safe, stable relationships.

Understanding the basic variety of fasteners helps you to select the best suitable one for your next DIY project. Fasteners for Every Purpose Whether you need fast assembly of nails, holding power of screws or the permanence of rivets, there is a fastener to suit your needs.

When Are Nails Best?

Large Projects

While nails are typically the go-to for bigger jobs like framing up a house or putting down a deck, This rapid installation time makes them a perfect fit for tasks where this speed and efficiency is paramount. If you are nailing them, meanwhile, you can simply hammer them into materials and save on time for labor.

This is fine for big jobs, as nails give you some flexibility. They can soak up a little movement and bend without breaking, so for building which may move around or expand slightly, they can be good. This becomes particularly useful if you are working with wood since materials may expand and contract based on temperature.

Nails are easy to use for big projects, but it pays you to think about their holding power. Adding nails/fasteners in certain places, or replacing them with screws can provide extra strength to the joint.

Finish Carpentry

Finish carpentry typically consists of more detail-oriented work where function is equal to aesthetics. This is why nails are a popular pick in the field, since they have small heads that can be painted over or hidden easily. Which does make them ideal for trim, molding, and cabinetry.

Nails have the advantage of being easier to apply, especially during finish carpentry. This is because of their smooth design that aids with faster installation without pre-drilling, a huge time saver. This is especially beneficial for complex designs or tight locations.

In those projects in which the aesthetics of fasteners is a must, nails are an ideal way to go. Using nails for finish carpentry means you never Sacrifice quality craftsmanship for a polished look.

When Are Screws Best?

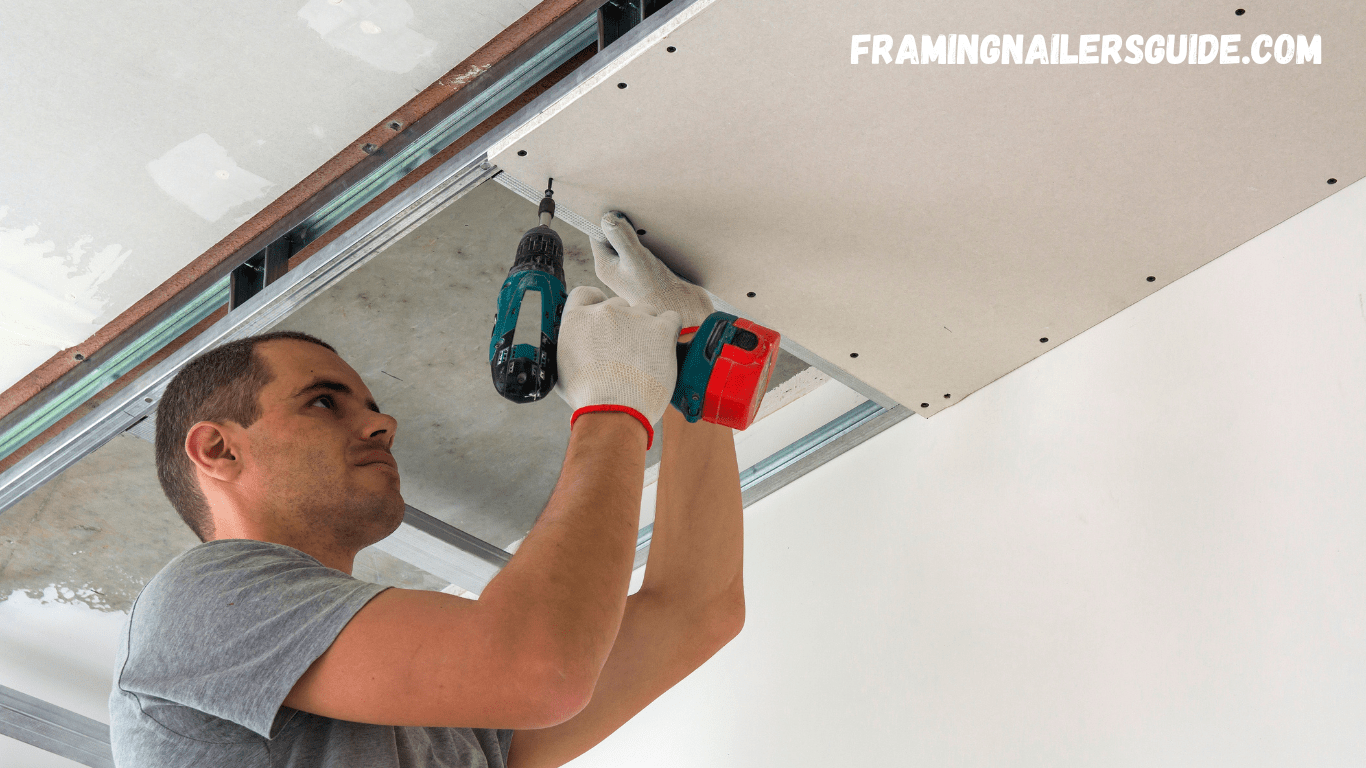

Design of Structural projects as well as Heavy-Load Installations

In terms of structural projects and load-bearing devices, the screws are generally preferred. The thread design gives these nails outstanding holding power, which makes them useful for tasks requiring a strong and dependable connection. Screws are therefore the ideal fastener type for furniture construction, shelves installation and any place that heavy machinery needs to be secured.

Screws, on the other hand, have an edge in terms of precision for structural projects. These can be installed with no splitting of the material, and can even be adjusted in size to perfection. This is particularly necessary in projects where alignment and balance are key.

Where there are weight-bearing elements in a task, screws lend stability to an extent that guarantees safety and durability. Choosing screws for structural projects will help you know that your constructions can withstand time and last longer than other methods of connections.

Short Term and Low Volume Projects

Screws excel in other areas too — temporary and smaller projects that benefit from removability. Easy to unscrew due to the threaded design, bolts are suited for projects that need disassembling or adjusting such as building temporary fixtures or prototypes.

For smaller projects, they provide the precision and control needed. You can drive them in and out without harming the material, making them a versatile choice for applications where precision is crucial. This attribute is especially helpful with crafts or hobbies where you need to change things often.

Screws — In projects where inversion and reversibility are the name of the game, screws are perfect. Go for screws on temporary and smaller projects; they are less stable than wood joinery but allow for easy adjustment.

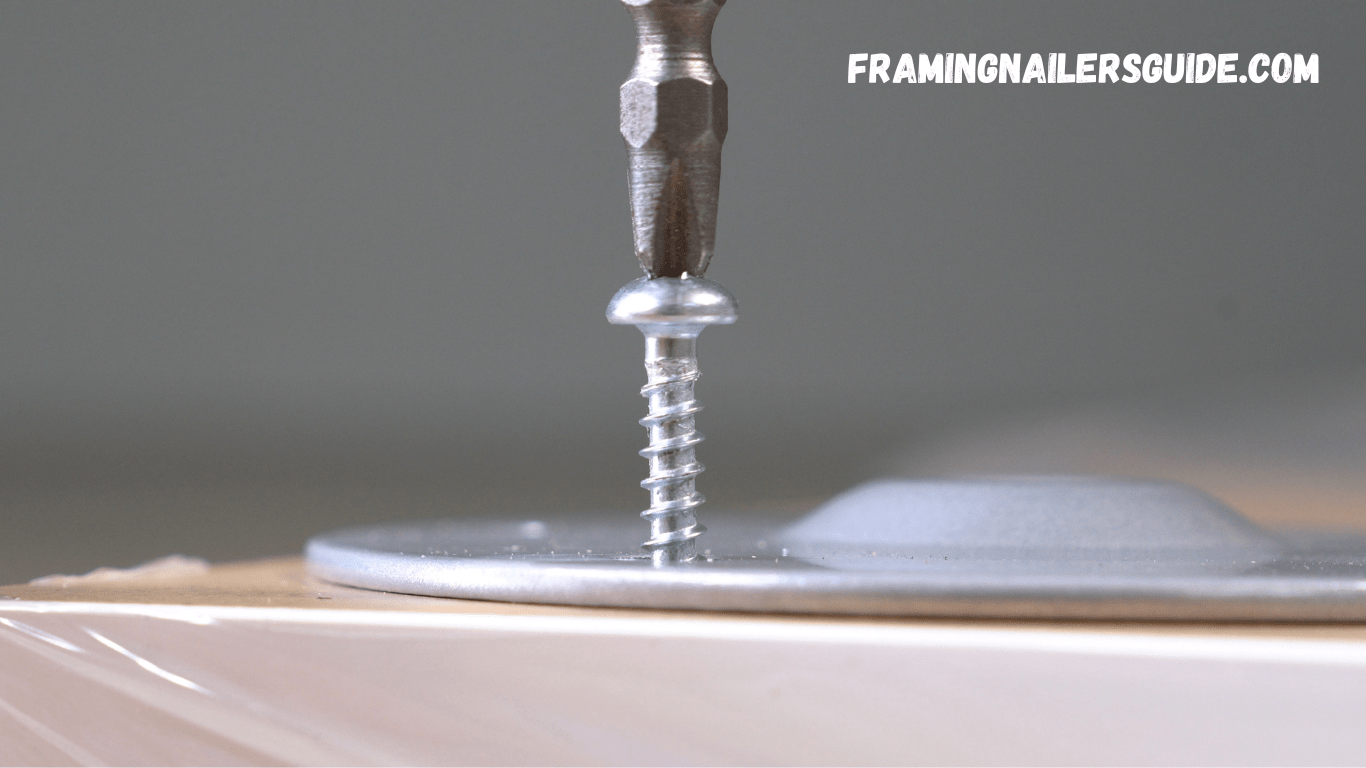

Drywall or Gypsum Board

Screws are more commonly used as fasteners when it comes to drywall or gypsum board because of the way they anchor. They also provide a flat surface against which you can attach finishing materials with less fuss and higher success. This is a threaded design so they attach to wall studs and will not sag or move after time if placed properly.

Whereas in terms of screw, it offers little to no surface damage which is an advantage when installing drywall. Screws cause the surface to finish flush with no bulging and cracking like nails which makes patching, painting a whole lot easier. Which gives it a cleaner look, and prevents any future repairs.

For projects that incorporate either drywall or gypsum board, screws are the best option for a solid finish. Utilizing screws in these installations help you lock in the quality of your work for the long haul.

Frequently Asked Questions

Why use nails instead of screws for framing?

Nails provide superior shear strength so it is common to use them rather than screws for framing. This means they can soak up the lateral forces as needed and move along with the building, which helps to keep the wood from splitting or cracking. Nails also install faster, which makes them ideal for nailing up tons of framing quickly.

Can I hammer in a screw?

Sure, you could theoretically hammer in a screw — but don’t. Because they have threads, screws are made to be driven in with a screwdriver or drill and hold everything tight. When you hammer or strike down a screw, it deforms the threads and reduces the power of hold and firmness of the connection. Use the right tool to install screws and get optimal results.

Is it better to use nails or screws on a deck?

When building a deck, nails or screws can be the right choice depending on user needs at specific situations. Deck screws are typically the go-to deck fasteners due to their superior holding power and ability to keep boards from subsequently loosening over time. Nails can instead be used for framing and other elements where flexibility and shear strength are more important than tensile strength [10].

Which Screw for Framing?

Choosing Your Screws — Framing So You’re Only. Coarse threaded screws are appropriate for aligning timber, whereas fine threaded screws can be used with steel. The screws should be long enough to stabilize the material without coming out the other side.

What is the advantage of a screw over a nail?

| Penetration | Load capacity Nail | Load capacity Screw |

|---|---|---|

| 0 – 1 inch – 0 – 25mm | 53 lb – 25 kg | 625 lb – 285 kg |

| 1 – 1.5 inch – 25 – 40mm | 98 lb – 45 kg | 705 lb – 320 kg |

| 1.5 – 2 inch – 40 – 50 mm | 220 lb – 100 kg | 875 lb – 400 kg |

| 2 – 2.5 inch – 50 – 65mm | 319 lb – 145 | 1580 lb – 720 kg |

The threaded design is intended, and the main reason for screws to have greater holding power than a nail. They offer a tight, secure fit that prevents the connection from being pulled apart so they are perfect for projects where you need to ensure everything stays in place. Furthermore, screws provide removal and modification that do not damage the material being installed, thus flexibility for temporary or adjustable installations.

In Conclusion

Selecting between nails vs screws can make or break your projects! Know where each fastener type excels or falls short and pick the best option for your needs to ensure durability and longevity. This guide has you covered in everything from understanding the involved stress factors to knowing when each fastener excels; crushed with knowledge so that you can tackle any of your projects confidently.

Whether the project is large-scale construction or a delicate craft, choosing the right fastener makes all the difference. I hope the guidance provided in this post can help you raise your DIY home improvement game and achieve pro results every time!

If you want to learn more, there are plenty of resources around the web to gain deeper insight into fasteners and their use. Spend time researching & watching videos on the type of project you are doing & enjoy an effortless, beneficialContinue reading Efficient DIYing–Less Work Better Results more enjoyable vibe in yourContinue reading Inspire Others to Pick Up the Hammer incorporate thoseDIY fun.