Table of Contents

Last Updated on December 2, 2024 by John Patterson

For hands-on hobbyists and pro woodworkers alike, nail guns are power tools that help projects go quicker, more precisely, and with less wear and tear. But have you wondered how much does it take to make a nail gun from scratch? If you’re planning on building one for fun, function, or just an experiment, it’s essential to know the costs associated.

This guide will address the most important aspects and the procedures involved in producing a nail gun so you can weigh your options and decide whether it would be worth the effort or not.

Five Aspects Critical to the Construction of a Nail Gun

Here are the core things you need to think of before starting the project:

Nail Gun Type:

The type of nail gun you want to build (pneumatic, cordless, or electric) greatly affects your costs and complexity.

Parts and Materials :

The cost of parts like air compressors, batteries, electric motors, and triggers vary widely and must be carefully obtained.

Quality:

Paying for decent materials will cost you more, but you’ll have a longer-lasting tool that’s also safer to operate.

Special Features and Accessories:

Support for special features such as depth adjustment settings, bump-fire mode, and LED lights comes with added work and expense.

Safety Mechanisms:

Since safety is not optional in such devices, including safety mechanisms entails an added cost and complexity.

Tools Required:

You will also need tools like drills, a soldering iron, and so on to assemble the nail gun parts.

Skills and Expertise:

Building a nail gun is not a beginner project. An understanding of the electrical and mechanical aspects will prove invaluable.

What Kind of Nail Gun do you intend to Produce?

Deciding which nail gun to build will affect your design choices and total costs. Here’s a closer look at the main types of nail guns:

Pneumatic Nail Guns

Pneumatic nail guns are powered by compressed air and are the most used. They are great for big projects such as framing or roofing. Pneumatic nail guns are powerful, but to make them functional, you’ll also have to get an air compressor. This added requirement translates to higher initial costs.

Estimated Costs to Make

- Air Compressor Component: 50–150$

- Firing Mechanism & Body Frame: $30–$70

- Miscellaneous Parts (hoses, hardware, seals): $20–$50

- Estimated Total Cost: $100–$270

Cordless Nail Guns

Portable and powered by rechargeable batteries, cordless nail guns can be used in a variety of applications. But adding battery compatibility and electronics complicates production.

Estimated Costs to Make

- Battery and Charging Unit: $40 — $100

- Drive Motor and Circuit Parts: $50–$150

- Tool Body and Firing Mechanism Materials: $30–60

- Final Estimated Cost: $120–$310

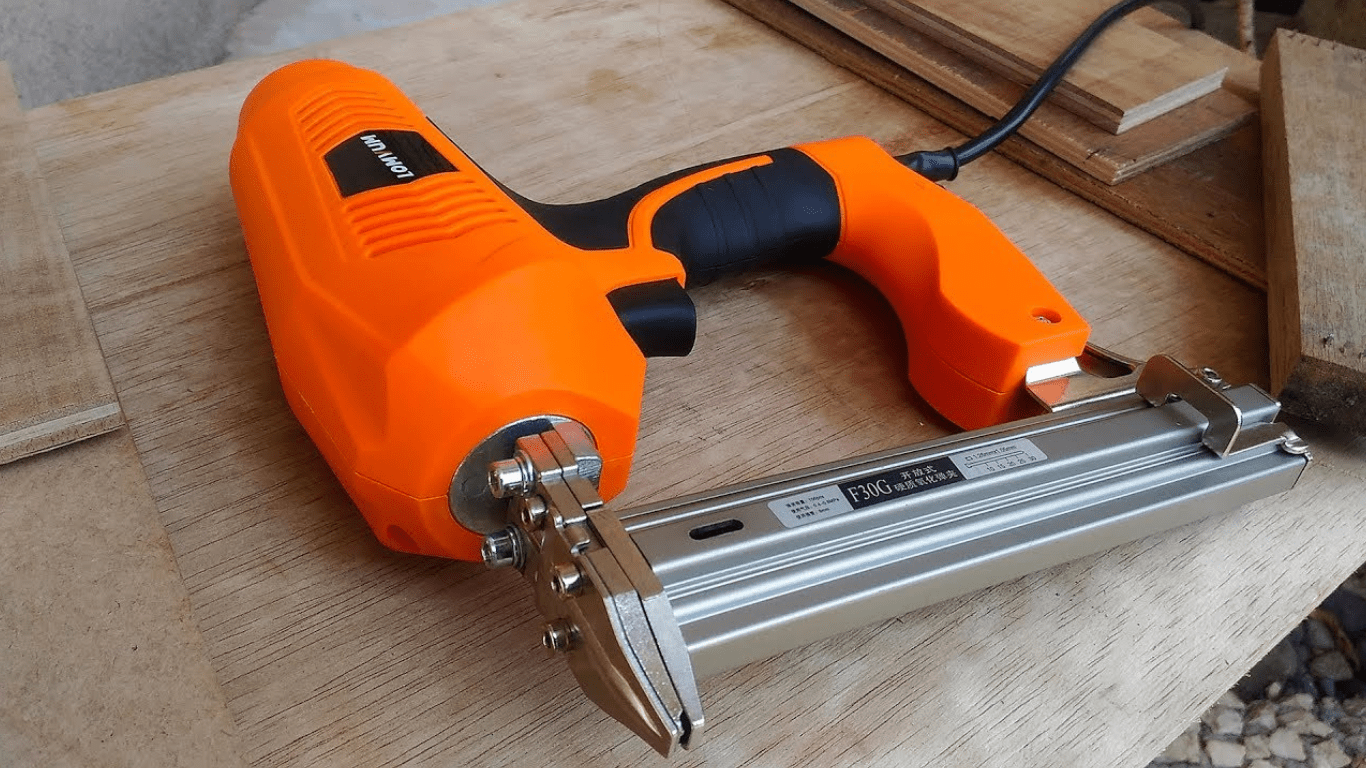

Electric Nail Guns

They need direct electric power to work and are usually used for less demanding jobs such as finishing and small DIY projects. They’re not as strong as the pneumatic or cordless types, but they’re easy and inexpensive to put together.

Estimated Costs to Make

- Electric motor and trigger system: $25–50

- Electric Cord and Power Assembly Components: $15–$40

- Nail loader and firing mechanism: $20–$50

- Total Estimated Cost: $60–$140

Considerations For Nail Gun Making

Type of Nail Gun

The kind of nail gun — pneumatic, cordless, or electric — has a drastic effect on the design, raw materials and price point needed. DIY builders needing the occasional tool can find inexpensive alternatives to the pneumatic nail guns, which are the most expensive of the group.

Quality

A nail gun must be built using quality materials for its body, seals, and firing mechanisms to create a strong and durable tool. Cheap materials drive down costs although they may sacrifice safety and durability.

Example Comparison

- The cost of a quality compressor seal: $15–$30

- Cheap Compressor Seal: $5 – $10

Features and Accessories

optional features such as depth settings, sequential firing, ergonomic grips, and safety switches can add considerable cost and complexity to your project.

Nail Size and Capacity

Does your nail gun have compatibility with a variety of nail sizes and capacities? A broader compatibility range would typically require a more complex mechanism and larger magazine size, increasing costs.

Making the Right Choice

After you’ve factored in these considerations, you should ask yourself these questions before you begin your project:

What does it need to do (e.g., home projects, heavy-duty construction)?

Do you have the technical skills/tools to put the pieces together?

Are you making it in-house so you can save money, or is it an exercise in learning?

Is it worth the time to build them, or should someone just buy a proper nail gun?

Pro Tip: Building a nail gun is an awesome project, though not one we’d recommend for beginners. If conserving funds is your top priority, a factory-made nail gun will likely be cheaper and more efficient than making your own.

Frequently Asked Questions

Q1. How much does it cost to weld a nail gun?

For the most part, investing in a nail gun is the most economical. Add up materials, tools and time to make a nail gun, and it’s usually more expensive than what you can buy any entry-level model for.

Q2. How long does it take to develop a nail gun?

It can take anywhere from a few days to a couple of weeks to assemble and test your nail gun, depending on your experience and the availability of parts.

Q3. Is it safe to construct a nail gun by yourself?

There are so many variables as to whether that is safe, based on the quality of the gun itself, how it was constructed, and how it was tested. Always use protective gear when using your DIY nail gun and ensure little safety mechanisms are in place.

Q4. Is it possible to hack a store-bought nail gun instead of building one?

Yes. This allows you to get an existing nail gun, customize some parts, and save time and effort while at the same time personalizing some of the features.

Build It or Buy It?

For those with the required skills, patience, and manufacturing tools, a nail gun is a fun project to make. That said, for most hobbyists, there would probably be a safer, higher-performance nail gun available for sale than one that you build yourself.

If you love a challenge in DIY-ing, you could learn some valuable skills with a nail gun you made yourself. Part of this will depend on your own preferences, but regardless make sure to focus on quality and safety.

Happy building! 💪